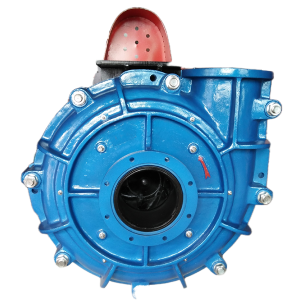

Wholesale OEM Centrifugal Slurry Pump Corrosion Resistance Rubber Lined Pump Spare Parts

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for Wholesale OEM Centrifugal Slurry Pump Corrosion Resistance Rubber Lined Pump Spare Parts, To provide customers with excellent equipment and services, and constantly develop new machine is our company’s business objectives. We look forward to your cooperation.

We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for China Slurry Pump Parts and Warman Pump Accessories, Insisting on the high quality generation line management and customers pro assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

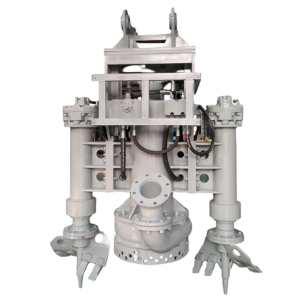

6x4D-TG Gravel Pump is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life.

Design Features

• Horizontal, cantilevered, single-casing structure, centrifugal pump design.

• Wide passage, good performance of NPSH, Anti-wearing and anti-corrosion, high efficiency.

• Cylinder bearing assembly, grease lubrication, adjusting the distance between impeller and pump.

• Mechanical seal, expeller seal and packing seal for selection.

• Driving type: Direct connection, VFD, V-belt drive, gearbox drive, elastic coupling drive, fluid coupling drive.

• Easy installation, discharge outlet can be adjusted at any direction of 360°.

6x4D-TG Gravel Pump Performance Parameter

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

6x4D-TG |

60 |

36-250 |

5-52 |

600-1400 |

58 |

2-5.5 |

378 |

6x4D-TG Gravel Pump Parts Structural

|

Base Code |

Part Name |

6/4D-TG |

|

003 |

Base |

D003M |

|

005 |

Bearing Assembly |

DAM005M |

|

013 |

Door |

|

|

024 |

End Cover |

D024 |

|

028 |

Expeller |

DAM028 |

|

029 |

Expeller Ring |

DAM029 |

|

032 |

Adaptor Plate |

DG4032M |

|

041 |

Back Liner |

DG4041 |

|

044 |

Gland |

D044 |

|

062 |

Labyrinth |

D062 |

|

063 |

Labyrinth Ring |

D063 |

|

064 |

Impeller O-ring |

F064 |

|

067 |

Neck Ring |

D067 |

|

073 |

Shaft |

DAM073M |

|

075 |

Shaft Sleeve |

D075 |

|

078 |

Stuffing Box |

DAM078 |

|

108 |

Piston Ring |

|

|

109 |

Shaft O-ring |

D109 |

|

111 |

Packing |

D111 |

|

117 |

Shaft Spacer |

DAM117 |

|

118 |

Lantern Restrictor |

D118 |

|

122 |

Expeller Ring/Stuffing Box Seal |

D122 |

|

124 |

Bowl Sea/Door Seal |

DG6124 |

|

130 |

Flange |

|

|

131 |

Bowl |

DG4131 |

|

132 |

Discharge Joint Ring |

E4132 |

|

134 |

Clamp Ring |

|

|

135 |

Clamp Ring |

E6135 |

|

137 |

Impeller |

DG4137 |

|

138 |

Grease Cup Adaptor |

|

|

221 |

Discharge Flange |

DG4221 |

|

239 |

Impeller Release Collar |

|

|

292 |

Door Clamp Plate |

Note:

6×4 D-TG gravel pumps and spares are only interchangeable with Warman® 6×4 D-G gravel pumps and spares.We retain bettering and perfecting our goods and service. At the same time, we perform actively to do research and enhancement for Wholesale OEM Centrifugal Slurry Pump Corrosion Resistance Rubber Lined Pump Spare Parts, To provide customers with excellent equipment and services, and constantly develop new machine is our company’s business objectives. We look forward to your cooperation.

Wholesale OEM China Slurry Pump Parts and Warman Pump Accessories, Insisting on the high quality generation line management and customers pro assistance, we now have designed our resolution to supply our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |