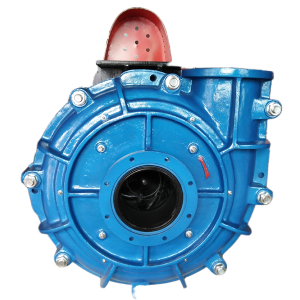

Wholesale Discount China High Quality Rubber Lined Slurry Pump for Mining Processing (AHR)

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Wholesale Discount China High Quality Rubber Lined Slurry Pump for Mining Processing (AHR), We are also continuously hunting to establish relationship with new suppliers to supply progressive and intelligent alternative to our valued shoppers.

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for China Slurry Pump, Wn Pump, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We’ve been confident that we’ve been going to have a bright prospect and to be distributed all over the world in the years to come.

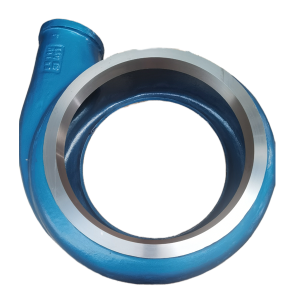

THR rubber lined slurry pumps are similar to AH metal lined slurry pump in structure. The main difference between AH and THR is the material of wetted parts, which are natural rubber, synthetic rubber or other wear-resistant rubbers. THR rubber lined slurry pumps are more suitable in delivering strong corrosive or abrasive slurries of small particle size without sharp edges.

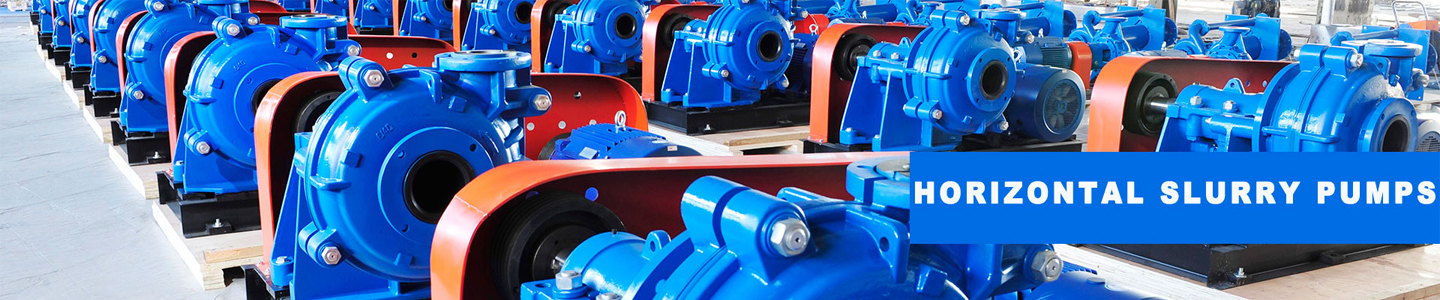

Design Features:

√ Heavy duty construction with through-bolt design provides ease of maintenance and minimal downtime.

√ Ductile iron fully lined casing provides durability, strength, safety, and long service life.

√ Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and low operating costs.

√ Large, open internal passages designed to reduce internal velocities, maximise wear life and lower operating costs.

√ Thick elastomer or alloy bolt-in liners provide superior corrosion resistance plus offer ease of liner change-out and interchangeability to reduce overall maintenance costs and maximise wear life.

√ Minimal shaft/impeller overhang reduces shaft deflection and increases packing life.

√ Cartridge-style bearing assembly allows for maintenance in a clean environment without removal of the slurry pump, resulting in reliable operation and prolonged bearing life.

√ Grease or oil lubrication bearing assembly options offer ease of maintenance and reduced downtime.

√ Optional dry running shaft seal reduces or eliminates flush water requirements.

√ Effective expeller prolongs packing life while reducing or eliminating flush water requirement.

√ Interchangeability of seal arrangements – full flush, low flow, centrifugal, or mechanical seals may be fitted to any sized slurry pump.

THR Rubber Lined Slurry Pumps Performance Parameters:

|

Model |

Max. Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q (m3/h) |

Head H (m) |

Speed n (rpm) |

Eff. η (%) |

NPSH (m) |

|||

|

1.5/1B-THR |

15 |

Rubber |

Rubber |

10.8-25.2 |

7-52 |

1400-3400 |

35 |

2-4 |

3 |

|

2/1.5B-THR |

15 |

Rubber |

Rubber |

25.2-54 |

5.5-41 |

1000-2600 |

50 |

3.5-8 |

5 |

|

3/2C-THR |

30 |

Rubber |

Rubber |

36-75.6 |

13-39 |

1300-2100 |

55 |

2-4 |

5 |

|

4/3C-THR |

30 |

Rubber |

Rubber |

79.2-180 |

5-34.5 |

800-1800 |

59 |

3-5 |

5 |

|

4/3D-THR |

60 |

Rubber |

Rubber |

79.2-180 |

5-34.5 |

800-1800 |

59 |

3-5 |

5 |

|

6/4D-THR |

60 |

Rubber |

Rubber |

144-324 |

12-45 |

800-1350 |

65 |

3-5 |

5 |

|

6/4E-THR |

120 |

Rubber |

Rubber |

144-324 |

12-45 |

800-1350 |

65 |

3-5 |

5 |

|

8/6E-THR |

120 |

Rubber |

Rubber |

324-720 |

7-49 |

400-1000 |

65 |

5-10 |

5 |

|

8/6R-THR |

300 |

Rubber |

Rubber |

324-720 |

7-49 |

400-1000 |

65 |

5-10 |

5 |

|

10/8ST-THR |

560 |

Rubber |

Rubber |

540-1188 |

12-50 |

400-750 |

75 |

4-12 |

5 |

|

10/8E-M |

120 |

Rubber |

Rubber |

540-1188 |

10-42 |

500-900 |

79 |

5-9 |

5 |

|

12/10ST-THR |

560 |

Rubber |

Rubber |

720-1620 |

7-45 |

300-650 |

80 |

2.5-7.5 |

5 |

|

14/12ST-THR |

560 |

Rubber |

Rubber |

1152-2520 |

13-44 |

300-500 |

79 |

3-8 |

5 |

|

16/14ST-THR |

560 |

Rubber |

Rubber |

1368-3060 |

11-63 |

250-550 |

79 |

4-10 |

5 |

|

18/16TU-THR |

1200 |

Rubber |

Rubber |

2160-5040 |

8-66 |

200-500 |

80 |

4.5-9 |

5 |

|

20/18TU-THR |

1200 |

Rubber |

Rubber |

2520-5400 |

13-57 |

200-400 |

85 |

5-10 |

5 |

THR Rubber Lined Slurry Pumps Applications:

THR series rubber slurry pumps are widely used in Mineral processing, Ball mill discharge, Bottom/fly ash, lime grinding, Coal, Coarse sand, Coarse tailings, Dredging, FGD, Fine tailings, Cyclone feed, Flotation, Heavy media, Minerals concentrate, Mineral sands, Ni acid slurry, Oil sands, Tallings, Phosphoric acid, Phosphate matrix, Process chemical, Pulp and paper, Rod mill discharge, SAG mill discharge, Wet crushers etc.

* THR rubber lined slurry pumps and spares are only interchangeable with Warman® THR rubber lined slurry pumps and spares.

Assume full obligation to meet all demands of our customers; accomplish ongoing advancements by promoting the advancement of our customers; become the final permanent cooperative partner of clientele and maximize the interests of shoppers for Wholesale Discount China High Quality Rubber Lined Slurry Pump for Mining Processing (AHR), We are also continuously hunting to establish relationship with new suppliers to supply progressive and intelligent alternative to our valued shoppers.

Wholesale Discount China Slurry Pump, Wn Pump, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We’ve been confident that we’ve been going to have a bright prospect and to be distributed all over the world in the years to come.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |