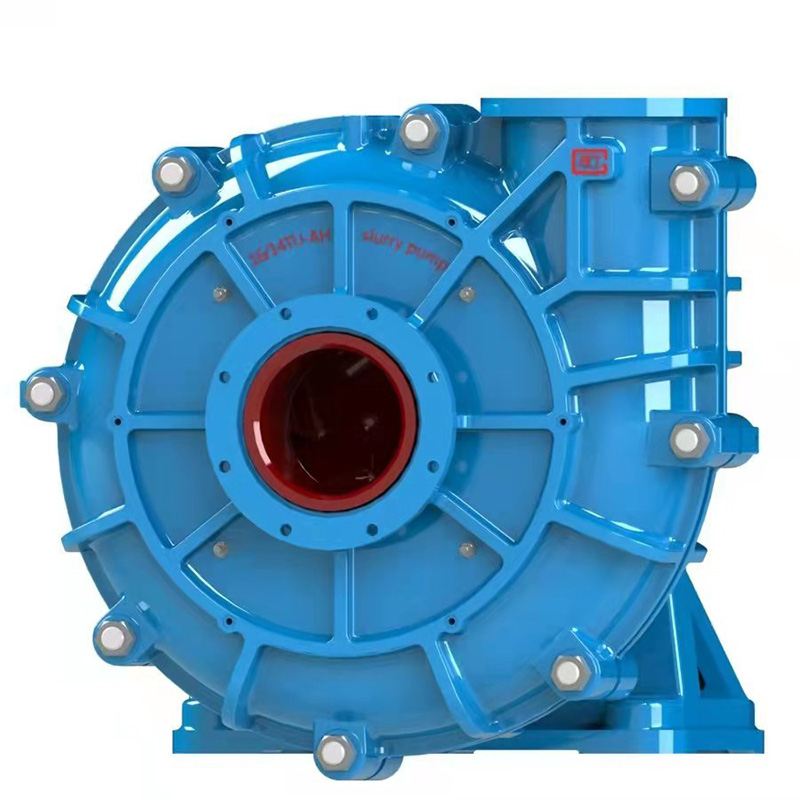

Top Quality Slurry Tank Pump - Rubber Lined Slurry Pump Parts – Ruite Pump

Top Quality Slurry Tank Pump - Rubber Lined Slurry Pump Parts – Ruite Pump Detail:

Rubber Lined Slurry Pump Parts namely the rubber parts have direct connection with slurries, They are very easily worn-out components because they work under longtime impact of abrasive and corrosive slurries in the high speed, The wetted parts include impeller, cover plate liner, frame plate liner, throatbush, frame plate liner insert etc, These wear parts are very crucial to the service life of slurry pumps, For the long service life of pump parts, the material plays an important role here, Tobee offers rubber slurry pump parts are more suitable for delivering strong corrosive or abrasive slurries of small particle size without sharp edges.

Slurry Pump Rubber Wear Parts

√ Liners – Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

√ Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are complete interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

√ Throatbush – Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

Rubber Materials Type And Data Descriptions

|

code |

Material name |

Type |

Description |

|

RU08 |

Standard Impeller Rubber |

Natural Rubber |

RU08 is a black natural rubber, of low to medium hardness. R08 is used for impellers where superior erosive resistance is required in fine particle slurries. The hardness of RU08 makes it more resistant to both chunking wear and dilation (i.e.: expansion caused by centrifugal forces) as compared to RU26. RU08 is generally only used for impellers. |

|

RU26 |

Anti Thermal Breakdown Rubber |

Natural Rubber |

RU26 is a black, soft natural rubber. It has superior erosion resistance to all other materials in fine particle slurry applications. The antioxidants and antidegradents used in RU26 have been optimized to improve storage life and reduce degradation during use. The high erosion resistance of RU26 is provided by the combination of its high resilience, high tensile strength and low Shore hardness. |

|

RU33 |

Natural Rubber (Soft) |

Natural Rubber |

RU33 is a premium grade black natural rubber of low hardness and is used for cyclone and pump liners and impellers where its superior physical properties give increased cut resistance to hard, sharp slurries. |

|

RU55 |

Anti Thermal Natural Rubber |

Natural Rubber |

RU55 is a black, Anti-corrosive natural rubber. It has superior erosion resistance to all other materials in fine particle slurry applications. |

|

SY01 |

EPDM Rubber |

Synthetic Elastomer |

|

|

SY12 |

Nitrile Rubber |

Synthetic Elastomer |

Elastomer SY12 is a synthetic rubber which is generally used in applications involving fats, oils and waxes. S12 has moderate erosion resistance. |

|

SY31 |

Chlorosulfonated Polyethylene (Hypalon) |

Synthetic Elastomer |

SY31 is an oxidation and heat resistant elastomer. It has a good balance of chemical resistance to both acids and hydrocarbons. |

|

SY42 |

Polychloroprene (Neoprene) |

Synthetic Elastomer |

Polychloroprene (Neoprene) is a high strength synthetic elastomer with dynamic properties only slightly inferior to natural rubber. It is less effected by temperature than natural rubber, and has excellent weathering and ozone resistance. It also exhibits excellent oil resistance. |

|

SY45 |

High Temperature Hydrocarbon Resistant Rubber |

Synthetic Elastomer |

SY45 is an erosion resistant synthetic rubber with excellent chemical resistance to hydrocarbons at elevated temperatures. |

|

SY51 |

Fluoroelastomer (Viton) |

Synthetic Elastomer |

SN51 has exceptional resistance to oils and chemicals at elevated temperatures. Limited

erosion resistance |

Slurry Pump Rubber Parts Applications

Slurry Pump Rubber Parts are widely used for AH/HH/L/M Horizontal slurry pumps, SPR Vertical rubber lined slurry pumps, Centrifugal horizontal slurry pumps, Warman rubber lined slurry pumps, Chemical slurry pumps, Silica sand slurry pumps, Minerals processing slurry pumps, De-Watering Screen Pump, Ore sand pumps, Tailings Pump, Pipe-jacking slurry pumps, Ball mill discharge Pump, Tunnelling slurry pumps, Mixing tank slurry Pump, Wet crushers slurry pumps, SAG mill discharge pumps, Ball mill discharge pumps, Rod mill discharge slurry pumps, Ni acid slurry pumps, Coarse sand pumps, Coarse tailings pumps, Phosphate matrix slurry pumps, Scrubber slurry Pump, Minerals concentrate pumps, Heavy media slurry pumps, Dredging Sand slurry pumps, Bottom ash slurry pumps, Fly ash pumps, Lime grinding pumps, Screen feed Pump, Oil sands pumps, Mineral Sands pumps, Fine tailings pumps, Tailings booster Pump, Thickner Tailings Pump, Process recycle Pump, Pipeline transfer pumps, Phosphoric acid slurry pumps, Coal slurry pumps, Flotation pumps.

slurry pumps rubber parts and spares are only interchangeable with Warman® slurry pumps rubber parts and spares.

Product detail pictures:

Related Product Guide:

With this motto in mind, we've turn into one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for Top Quality Slurry Tank Pump - Rubber Lined Slurry Pump Parts – Ruite Pump , The product will supply to all over the world, such as: Bogota, Sudan, Los Angeles, We'd like to invite customers from abroad to discuss business with us. We can provide our clients with high quality products and excellent service. We are sure that we will have good cooperative relationships and make a brilliant future for both parties.

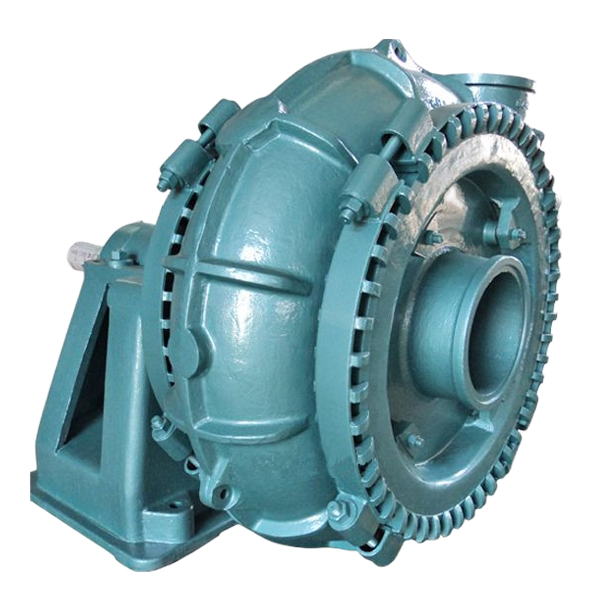

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.