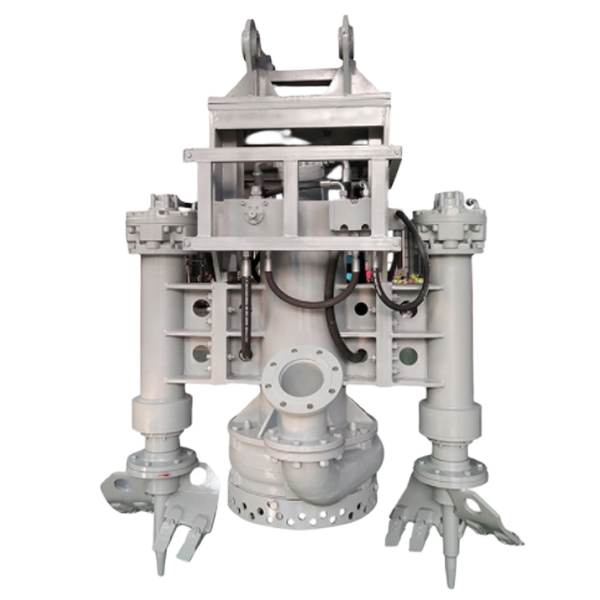

Super Lowest Price Industrial Slurry Pumps - 12/10F-TG Gravel Pump for Gravel transport – Ruite Pump

Super Lowest Price Industrial Slurry Pumps - 12/10F-TG Gravel Pump for Gravel transport – Ruite Pump Detail:

12x10F-TG Gravel Pump is a single stage, single casing, centrifugal horizontal pump driven by electric motor diesel engine. Large flow passage allows large particle solids, with advantages of high efficiency, wear resistant, wide flow channel, good ability of NPSH, stable performance, easy assembly, The discharge outlet can be adjusted at any direction, It is world’s standard for dredge, gravel or large particle slurries applications.

Design Features

• Advanced hydraulic model, CAD 3D design, high efficiency and obvious energy-saving.

• Large dredging sand depth, high density of dredging mud, good pump NPSH and strong suction lift ability.

• Strong through-put, The dredging pump can persistently discharge gravel, high plastic soil lump,etc.

• Wide application, The sand pump can be used in various kinds of soil quality.

• The TG sand pump can be directly matched with electric motor or diesel engine.

• The TG sand pump impeller is 3 or 5 vanes for large particles delivering.

• Little hydraulic loss, high efficiency and low oil-consumption.

• Steady operating, little vibration, low noise.

• Simple & reliable constriction, easily disassembly & assembly, convenient maintain.

• Reliable sealing without leakage.

• Long operating life of wear parts.

12/10F G Gravel Pumps Performance Parameters

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

12x10F-TG |

260 |

360-1440 |

10-60 |

350-700 |

65 |

1.5-4.5 |

667 |

12x10F-TG Gravel Pump Applications

• Mine: Black, non-ferrous ore slurry material pump and all kinds of concentrate and tailings conveying.

• Metallurgy: Transport various slurry for aluminium or steel manufacture.

• Coal: Coal mining, washing and various coarse and fine coal slurry transportation.

• Electricity: Remove power plant ash,wash ash,various ash dregs or ash slurry transportation.

• Construction materials: Various mud sand slurry(such as Cement slurry) transportation.

• Chemical: Phosphatic fertilizer or potassic fertilizer factory various abrasive slurry transportation.

• Water conservancy: Lake,river dredge, sediment,grit, High plastic clay Suction line to transportation.

Note:

12×10 F-TG gravel pumps and spares are only interchangeable with Warman® 12×10 F-G gravel pumps and spares.

Product detail pictures:

Related Product Guide:

continue to improve, to ensure product quality in line with market and customer standard requirements. Our company has a quality assurance system have been established for Super Lowest Price Industrial Slurry Pumps - 12/10F-TG Gravel Pump for Gravel transport – Ruite Pump , The product will supply to all over the world, such as: Myanmar, South Africa, Islamabad, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to deliver customers with high quality solutions, present high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

In China, we have many partners, this company is the most satisfying to us, reliable quality and good credit, it is worth appreciation.