Stainless steel Non-Clog sewage and sand dredge submersible mud pump

Stainless steel Non-Clog sewage and sand dredge submersible mud pump Introduction:

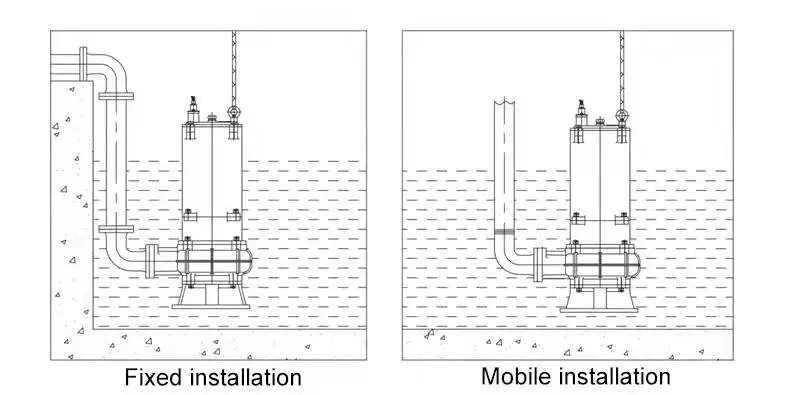

WQ sewage pump is a pump product developed by absorbing domestic and foreign water pump manufacturing experience. It has the characteristics of anti-winding, no clogging, automatic control and easy installation. The coupling rail can be used to install and unload the pump without contacting the sewage. It has a unique effect in discharging solid particles and long fiber waste.

Stainless steel Non-Clog sewage and sand dredge submersible mud pump Features

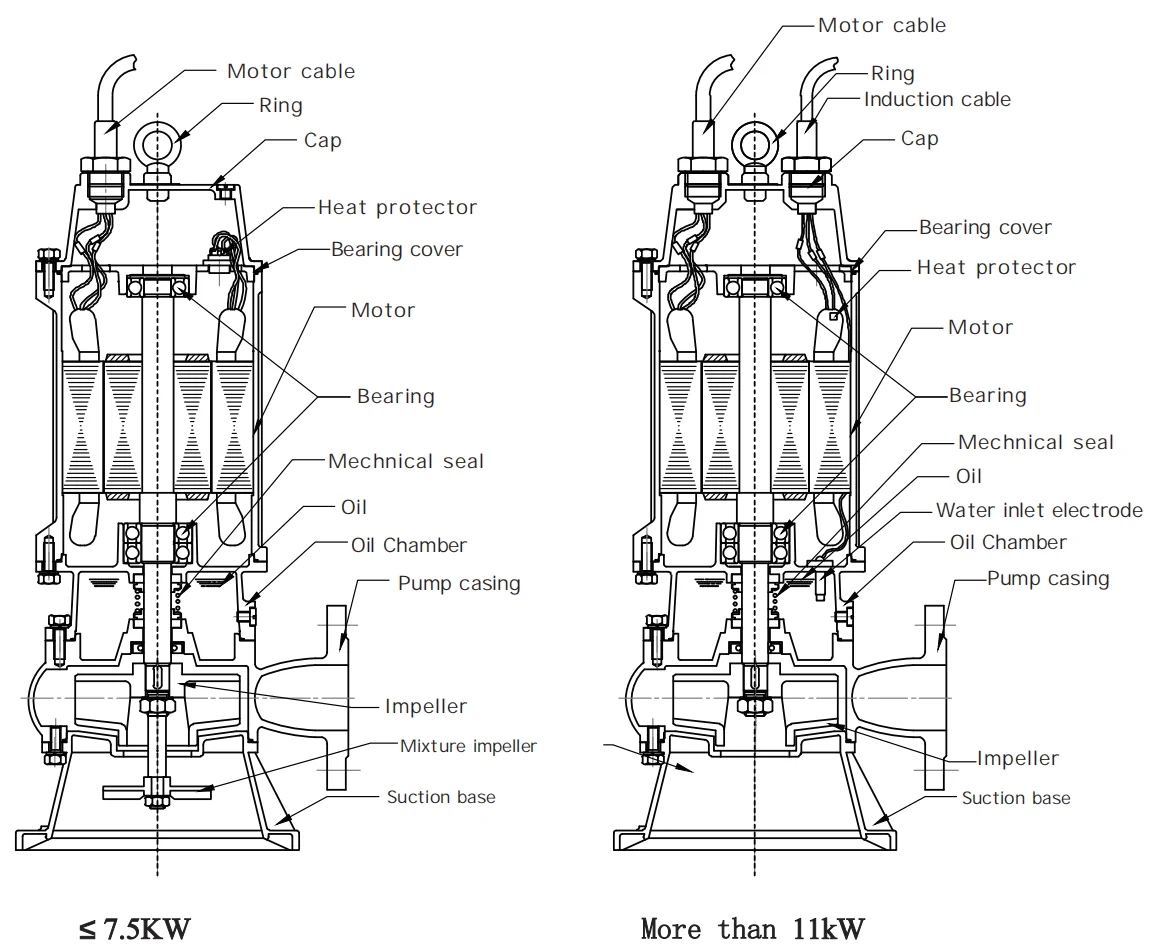

1. Adopt unique double-flow non-blocking impeller structure to improve the over-flow capacity and sewage discharge capacity of sewage.

2. The mechanical seal is a double-face mechanical seal, which is in the oil chamber for a long time to ensure the safe and reliable operation of the pump.

3. There is a water leakage detection probe in the pump wiring cavity. When there is water leakage, the probe sends out a signal, and the control system protects the pump. The company can be equipped with fully automatic safety protection control cabinet.

4. The motor stator adopts Class B and Class F insulation, and a thermal protector is built in. When the motor is overloaded and heated, the protector acts in time to implement absolute protection for the pump and motor.

Stainless steel Non-Clog sewage and sand dredge submersible mud pump Usage

1. Discharge of heavily polluted wastewater from factories and businesses.

2. Drainage system for urban sewage treatment, hospitals and hotels.

3. Sewage drainage station in residential area.

4. The water supply device of the civil air defense system drainage station and the water supply plant.

5. Municipal engineering and construction sites.

6. Attachment to the exploration, mining and power plants.

7. Rural biogas digesters, farmland irrigation, and river pond dredging.

Submersible Sewage Pump drawing

Submersible sewage pump Structure

| Model | Calibre (mm) |

Flow (m3/h) |

Head (m) |

Motor (kw) |

Speed (r/min) |

| 25WQ8-22-1.1 | 25 | 8 | 22 | 1.1 | 2825 |

| 32WQ12-15-1.1 | 32 | 12 | 15 | 1.1 | 2825 |

| 40WQ15-15-1.5 | 40 | 15 | 15 | 1.5 | 2840 |

| 40WQ15-30-2.2 | 40 | 15 | 30 | 2.2 | 2840 |

| 50WQ20-7-0.75 | 50 | 20 | 7 | 0.75 | 1390 |

| 50WQ10-10-0.75 | 50 | 10 | 10 | 0.75 | 1390 |

| 50WQ20-15-1.5 | 50 | 20 | 15 | 1.5 | 2840 |

| 50WQ15-25-2.2 | 50 | 15 | 25 | 2.2 | 2840 |

| 50WQ18-30-3 | 50 | 18 | 30 | 3 | 2880 |

| 50WQ25-32-5.5 | 50 | 25 | 32 | 5.5 | 2900 |

| 50WQ20-40-7.5 | 50 | 20 | 40 | 7.5 | 2900 |

| 65WQ25-15-2.2 | 65 | 25 | 15 | 2.2 | 2840 |

| 65WQ37-13-3 | 65 | 37 | 13 | 3 | 2880 |

| 65WQ25-30-4 | 65 | 25 | 30 | 4 | 2890 |

| 65WQ30-40-7.5 | 65 | 30 | 40 | 7.5 | 2900 |

| 65WQ35-50-11 | 65 | 35 | 50 | 11 | 2930 |

| 65WQ35-60-15 | 65 | 35 | 60 | 15 | 2930 |

| 80WQ40-7-2.2 | 80 | 40 | 7 | 2.2 | 1420 |

| 80WQ43-13-3 | 80 | 43 | 13 | 3 | 2880 |

| 80WQ40-15-4 | 80 | 40 | 15 | 4 | 2890 |

| 80WQ65-25-7.5 | 80 | 65 | 25 | 7.5 | 2900 |

| 100WQ80-10-4 | 100 | 80 | 10 | 4 | 1440 |

| 100WQ110-10-5.5 | 100 | 110 | 10 | 5.5 | 1440 |

| 100WQ100-15-7.5 | 100 | 100 | 15 | 7.5 | 1440 |

| 100WQ85-20-7.5 | 100 | 85 | 20 | 7.5 | 1440 |

| 100WQ100-25-11 | 100 | 100 | 25 | 11 | 1460 |

| 100WQ100-30-15 | 100 | 100 | 30 | 15 | 1460 |

| 100WQ100-35-18.5 | 100 | 100 | 35 | 18.5 | 1470 |

| 125WQ130-15-11 | 125 | 130 | 15 | 11 | 1460 |

| 125WQ130-20-15 | 125 | 130 | 20 | 15 | 1460 |

| 150WQ145-9-7.5 | 150 | 145 | 9 | 7.5 | 1440 |

| 150WQ180-15-15 | 150 | 180 | 15 | 15 | 1460 |

| 150WQ180-20-18.5 | 150 | 180 | 20 | 18.5 | 1470 |

| 150WQ180-25-22 | 150 | 180 | 25 | 22 | 1470 |

| 150WQ130-30-22 | 150 | 130 | 30 | 22 | 1470 |

| 150WQ180-30-30 | 150 | 180 | 30 | 30 | 1470 |

| 150WQ200-30-37 | 150 | 200 | 30 | 37 | 1480 |

| 200WQ300-7-11 | 200 | 300 | 7 | 11 | 970 |

| WQ200-250-11-15 | 200 | 250 | 11 | 15 | 970 |

| 200WQ400-10-22 | 200 | 400 | 10 | 22 | 1470 |

| 200WQ400-13-30 | 200 | 400 | 13 | 30 | 1470 |

| 200WQ250-15-18.5 | 200 | 250 | 15 | 18.5 | 1470 |

| 200WQ300-15-22 | 200 | 300 | 15 | 22 | 1470 |

| 200WQ250-22-30 | 200 | 250 | 22 | 30 | 1470 |

| 200WQ350-25-37 | 200 | 350 | 25 | 37 | 1980 |

| 200WQ400-30-55 | 200 | 400 | 30 | 55 | 1480 |

| 250WQ600-9-30 | 250 | 600 | 9 | 30 | 980 |

| 250WQ600-12-37 | 250 | 600 | 12 | 37 | 1480 |

| 250WQ600-15-45 | 250 | 600 | 15 | 45 | 1480 |

| 250WQ600-20-55 | 250 | 600 | 20 | 55 | 1480 |

| 250WQ600-25-75 | 250 | 600 | 25 | 75 | 1480 |

| 300WQ800-12-45 | 300 | 800 | 12 | 45 | 980 |

| 300WQ500-15-45 | 300 | 500 | 15 | 45 | 980 |

| 300WQ800-15-55 | 300 | 800 | 15 | 55 | 980 |

| 300WQ600-20-55 | 300 | 600 | 20 | 55 | 980 |

| 300WQ800-20-75 | 300 | 800 | 20 | 75 | 980 |

| 300WQ950-20-90 | 300 | 950 | 20 | 90 | 980 |

| 300WQ1000-25-110 | 300 | 1000 | 25 | 110 | 980 |

| 350WQ1100-10-55 | 350 | 1100 | 10 | 55 | 980 |

| 350WQ1500-15-90 | 350 | 1500 | 15 | 90 | 980 |

| 350WQ1200-18-90 | 350 | 1200 | 18 | 90 | 980 |

| 350WQ1100-28-132 | 350 | 1100 | 28 | 132 | 740 |

| 350WQ1000-36-160 | 350 | 1000 | 36 | 160 | 740 |

| 400WQ1500-10-75 | 400 | 1500 | 10 | 75 | 980 |

| 400WQ2000-15-132 | 400 | 2000 | 15 | 132 | 740 |

| 400WQ1700-22-160 | 400 | 1700 | 22 | 160 | 740 |

| 400WQ1500-26-160 | 400 | 1500 | 26 | 160 | 740 |

| 400WQ1700-30-200 | 400 | 1700 | 30 | 200 | 740 |

| 400WQ1800-32-250 | 400 | 1800 | 32 | 250 | 740 |

| 500WQ2500-10-110 | 500 | 2500 | 10 | 110 | 740 |

| 500WQ2600-15-160 | 500 | 2600 | 15 | 160 | 740 |

| 500WQ2400-22-220 | 500 | 2400 | 22 | 220 | 740 |

| 500WQ2600-24-250 | 500 | 2600 | 24 | 250 | 740 |

More size about submersible sewage pump, please contact us. Our technical people will choose the right pump for you.

If you need other types pump, please tell us your detail requirements, our technical people will choose the right pump for you.

Email: rita@ruitepump.com

Whatsapp/wechat: +8619933139867

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |