Short Lead Time for Slurry Pump Solutions - 10/8F-TG Gravel Pump, Highly efficient and stable – Ruite Pump

Short Lead Time for Slurry Pump Solutions - 10/8F-TG Gravel Pump, Highly efficient and stable – Ruite Pump Detail:

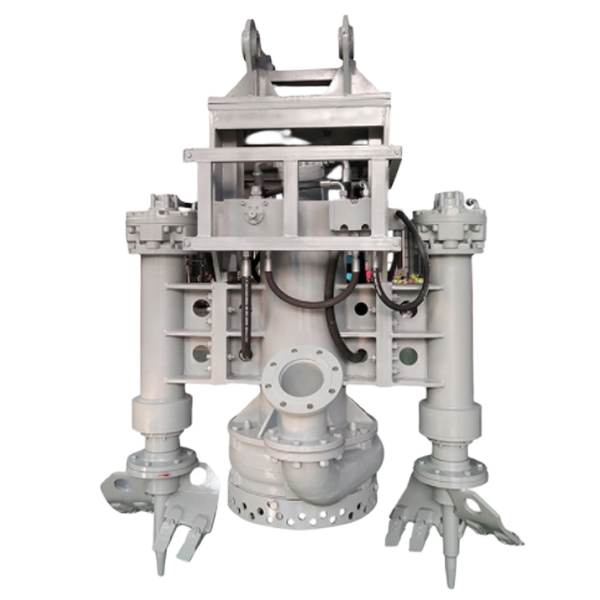

10x8F-TG Gravel Pump is the world’s standard for dredge and gravel applications. The range provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. A wide variety of shaft seals provide a perfect fit for a wide range of applications. Pass very large solids not capable of being pumped by AH series slurry pumps.

Design Features

• G gravel pump uses modern CAD design method, and has excellent hydraulic performance, high efficiency, and low wear rate.

• G gravel pump has wide runner, good anti-clogging performance, and excellent cavitation performance.

• G gravel pump uses expeller and filler combined seal and mechanical seal, ensuring that the slurry doesn’t leak.

• The reliability design greatly improves mean time between failures (MTBF) of complete machine.

• G gravel pump uses thin oil lubrication metric bearing, and rationally sets lubrication and cooling system to ensure that the bearing operates at low temperature.

• Flow passage components are made of special materials, so they have good wear resistance and corrosive resistance; after special processing, they are used for seawater dusting, and seawater and salt mist electric chemical corrosion conditions.

• In allowable pressure range, it can be used in series in stages, and allowable maximum working pressure is 3.6Mpa.

10/8F-TG Gravel Pump Performance Parameter

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

10/8F-TG |

260 |

216-936 |

8-52 |

400-800 |

65 |

3-7.5 |

533 |

10/8 Gravel Sand Pump Parts Structural

|

Base Code |

Part Name |

10/8F-TG |

10/8S-G |

10/8S-GH |

|

003 |

Base |

F003M |

S003M |

S003M |

|

005 |

Bearing Assembly |

F005M |

S005 |

S005 |

|

013 |

Door |

FG108013 |

FG108013 |

FGH8013 |

|

024 |

End Cover |

F024 |

S024 |

S024 |

|

028 |

Expeller |

F028 |

F028 |

FH028 |

|

029 |

Expeller Ring |

F029 |

F029 |

FH029 |

|

032 |

Adaptor Plate |

FG8032M |

FG8032M |

FGH8032 |

|

041 |

Back Liner |

FG8041 |

FG8041 |

FGH8041 |

|

044 |

Gland |

F044 |

F044 |

F044 |

|

062 |

Labyrinth |

F062 |

S062 |

S062 S062DM |

|

063 |

Labyrinth Ring |

F063 |

F063 |

F063 |

|

064 |

Impeller O-ring |

|||

|

067 |

Neck Ring |

F067 |

F067 |

F067 |

|

073 |

Shaft |

F073M |

S073 |

|

|

075 |

Shaft Sleeve |

F075 |

F075 |

F075 |

|

078 |

Stuffing Box |

F078 |

F078 |

FH078 |

|

108 |

Piston Ring |

F108 |

||

|

109 |

Shaft O-ring |

F109 |

F109 |

F109 |

|

111 |

Packing |

F111 |

F111 |

|

|

117 |

Shaft Spacer |

F117 |

F117 |

FG117 |

|

118 |

Lantern Restrictor |

F118 |

F118 |

F118 |

|

122 |

Expeller Ring/Stuffing Box Seal |

F122 |

FH122 |

F122 |

|

124 |

Bowl Sea/Door Seal |

FG10124 FG8124 |

FG10124 FG8124 |

G8124 |

|

130 |

Flange |

F10130 F8130 |

F10130 F8130 |

F10130 F8130 |

|

131 |

Bowl |

FG8131 |

FG8131 |

FGH8131 |

|

132 |

Discharge Joint Ring |

FG10132 F8132 |

FG10132 F8132 |

FG10132 F8132 |

|

134 |

Clamp Ring |

F134 |

F134 |

|

|

135 |

Clamp Ring |

F8135 |

F8135 |

FGH8135 |

|

137 |

Impeller |

FG8137 |

FG8137 |

FGH8137 |

|

138 |

Grease Cup Adaptor |

D138 |

D138 |

D138 |

|

221 |

Discharge Flange |

|||

|

239 |

Impeller Release Collar |

S239M |

||

|

292 |

Door Clamp Plate |

Note:

10×8 F-TG gravel pumps and spares are only interchangeable with Warman® 10×8 F-G gravel pumps and spares.

Product detail pictures:

Related Product Guide:

With advanced technologies and facilities, strict high-quality handle, reasonable rate, superior services and close co-operation with prospects, we are devoted to furnishing the best price for our customers for Short Lead Time for Slurry Pump Solutions - 10/8F-TG Gravel Pump, Highly efficient and stable – Ruite Pump , The product will supply to all over the world, such as: Rome, Cape Town, El Salvador, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!