Renewable Design for Slurry Booster Pump - Slurry Pump Rubber Throatbush – Ruite Pump

Renewable Design for Slurry Booster Pump - Slurry Pump Rubber Throatbush – Ruite Pump Detail:

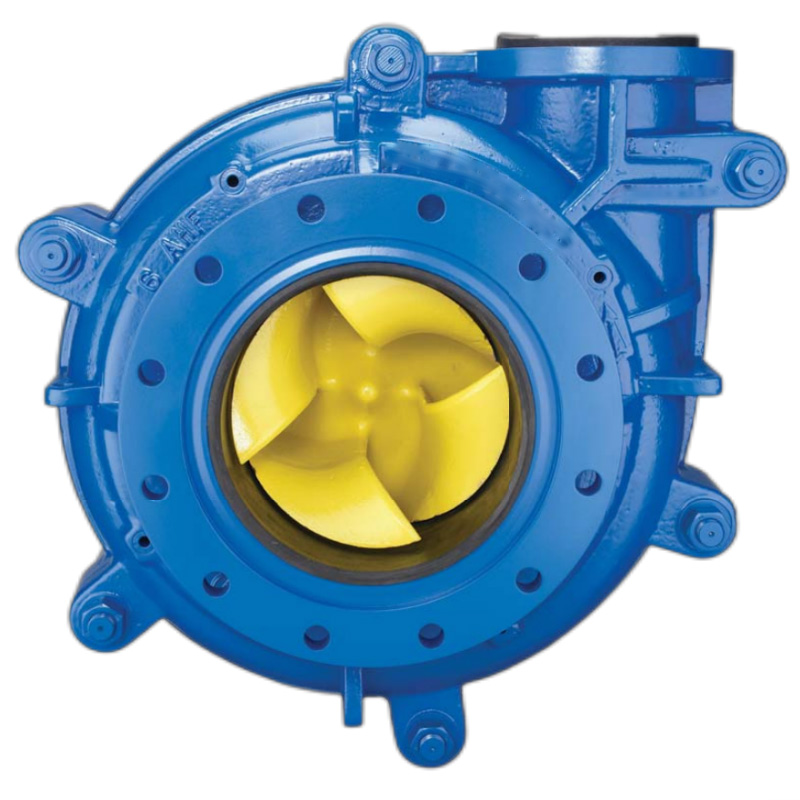

Slurry Pump Rubber Throatbush is the main wear parts for the rubber lined slurry pumps. It links plate liner and forms a pump chamber to work with impeller to contact with slurries, the rubber throatbush is normally made in natural rubber, special materials are also available.

These wear parts are very crucial to the service life of slurry pumps, For the long service life of pump parts, the material plays an important role here, Tobee offers rubber slurry pump parts are more suitable for delivering strong corrosive or abrasive slurries of small particle size without sharp edges.

Note:

slurry pump rubber throatbush is only interchangeable with Warman® slurry pump rubber throatbush.

Product detail pictures:

Related Product Guide:

We normally follow the basic principle "Quality Initial, Prestige Supreme". We've been fully committed to offering our consumers with competitively priced good quality merchandise, prompt delivery and professional support for Renewable Design for Slurry Booster Pump - Slurry Pump Rubber Throatbush – Ruite Pump , The product will supply to all over the world, such as: Cyprus, Finland, Greek, Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.