Renewable Design for Slurry Booster Pump - Rubber Frame Plate Liner – Ruite Pump

Renewable Design for Slurry Booster Pump - Rubber Frame Plate Liner – Ruite Pump Detail:

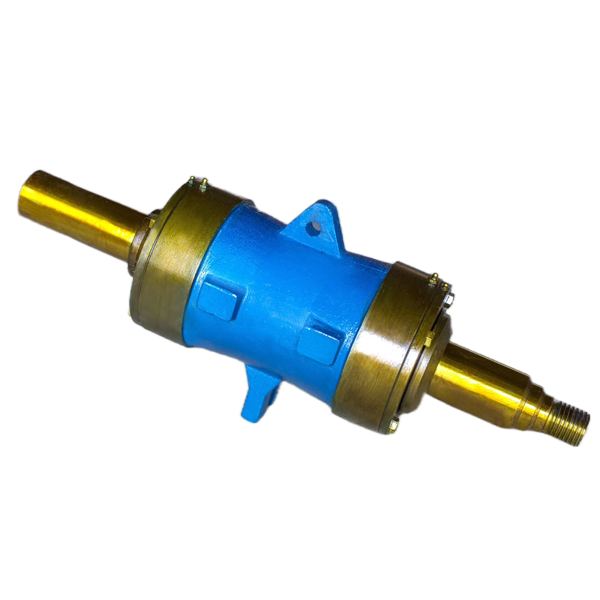

Slurry Pump Rubber Frame Plate Liner is the main wear parts for the rubber lined slurry pump. It forms a pump chamber with cover plate liner and throat bush to contact with slurries, As one of main wetted parts, Frame plate liner very easily worn-out components because it works under longtime impact of abrasive and corrosive slurries in the high speed conditions, So the materials is very crucial to lifetime of complete pump, Ruite provides a complete rubber materials selection for most all duties in mill.

Related Slurry Pump Rubber Wear Parts

√ Liners – Easily replaceable liners are bolted, not glued, to the casing for positive attachment and ease of maintenance. Hard metal liners are completely interchangeable with pressure molded elastomers. Elastomer seal rings back all liner joints.

√ Impeller – front and rear shrouds have pump out vanes that reduce recirculation and seal contamination. Hard metal and molded elastomer impellers are complete interchangeable. Cast in impeller threads require no inserts or nuts. High efficiency and high head designs are also available.

√ Throat bush – Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

Slurry Pump Frame Plate Liner List:

|

Frame Plate Liner |

AH Slurry Pump |

Materials |

|

B1036 |

1.5/1B-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

B15036 |

2/1.5B-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

C2036 |

3/2C-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

D3036 |

4/3C-AH, 4/3D-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

E4036 |

6/4D-AH, 6/4E-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

F6036 |

8/6E-AH, 8/6F-AH, 8/6R-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

F8036 |

10/8F-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

G8036 |

10/8ST-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

FAM10036 |

12/10F-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

G10036 |

12/10ST-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

FAM12036 |

14/12F-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

G12043 |

14/12ST-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

H14043 |

16/14TU-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

U18043 |

20/18TU-AH |

Natural rubber, Synthetic rubber, Polyurethane |

|

Frame Plate Liner |

L Slurry Pump |

Materials |

|

RSL30036 |

300S-L |

Natural rubber, Synthetic rubber |

|

S35043 |

350S-L |

Natural rubber, Synthetic rubber |

|

TL40043 |

400ST-L |

Natural rubber, Synthetic rubber |

|

TL45043 |

450ST-L |

Natural rubber, Synthetic rubber |

|

Frame Plate Liner |

M Slurry Pump |

Materials |

|

F8036 |

10/8E-M, 10/8F-M, 10/8R-M |

Natural rubber, Synthetic rubber, Polyurethane |

|

F10036 |

12/10F-M, 12/10R-M |

Natural rubber, Synthetic rubber, Polyurethane |

Applications of Rubber Slurry Pumps:

Slurry Pump Rubber Parts are widely used for Mining, Mineral Processing, Sand and Gravel, Coal Prep, Chemical Slurry Service, Cyclone Feeds, Aggregate Processing, Wet Crushers, SAG Mill Discharge, Fine Primary Mill Grinding, Tailings, Secondary Grinding, Bottom/fly ash slurries, Pulp And Paper, Food Processing, Cracking Operations, Gypsum Slurries, Pipeline Transport, High Velocity Hydraulic Transport, Food Processing, Explosive Sludge In Metal Smelting, River And Pond Dredging, Heavy Refuse Removal, Larger Particle Or Low NPSHA Applications, Continuous (Snore) Sump Pump Operation, Abrasive Slurries, High Density Slurries, Large Particle Slurries, Sump Drainage, Wash Down, Floor Drainage, Mixing, Iron Ore, Cooper, Diamond, Aluminum oxide, Gold, Kaolin, Phosphorite, Steel, Palm, Sugar, Chemical, Power, FGD, Frac Sand Blending, Waste water, Flotation etc.

Product detail pictures:

Related Product Guide:

We have been experienced manufacturer. Wining the majority of the crucial certifications of its market for Renewable Design for Slurry Booster Pump - Rubber Frame Plate Liner – Ruite Pump , The product will supply to all over the world, such as: Singapore, Portugal, Portugal, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!