Renewable Design for Slurry Booster Pump - Rubber Cover Pate Liner – Ruite Pump

Renewable Design for Slurry Booster Pump - Rubber Cover Pate Liner – Ruite Pump Detail:

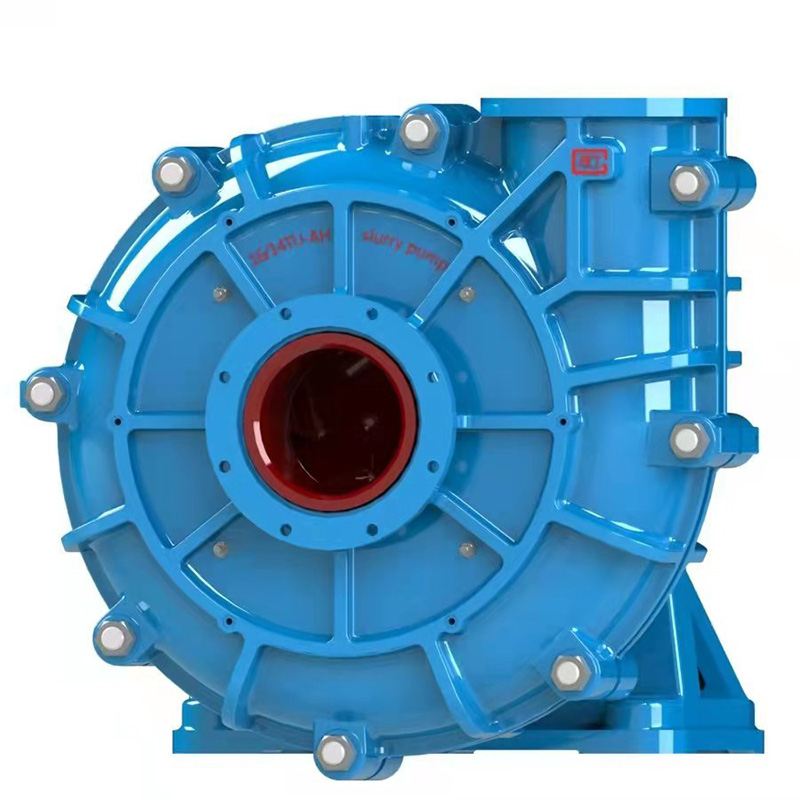

Slurry Pump Rubber Cover Plate Liner is the main wear parts for the rubber lined slurry pump. It forms a pump chamber with frame plate liner and throat bush to contact with slurries, As one of main wetted parts, Cover plate liner is very easily worn-out components because it works under longtime impact of abrasive and corrosive slurries in the high speed conditions, So the materials is very crucial to lifetime of complete pump, Ruite provides a complete rubber and metal materials selection for most all duties in mill.

Ruite offers a wide variety of natural rubber and synthetic rubber for the majority of slurry pump parts in both horizontal slurry pumps and vertical slurry pumps. A sample of our elastomer options: Natural Rubber, Neoprene, Hypalon, EPDM, Nitrile, Butyl, Polyurethane etc.

Rubber Slurry Pump Cover Plate Liner Code

|

Cover Plate Liner |

AH Slurry Pump |

Materials |

|

B1017 |

1.5/1B-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

B15017 |

2/1.5B-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

C2017 |

3/2C-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

D3017 |

4/3C-AH, 4/3D-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

E4018 |

6/4D-AH, 6/4E-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

F6018 |

8/6E-AH, 8/6F-AH, 8/6R-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

F8018 |

10/8F-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

G8018 |

10/8ST-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

FAM10018 |

12/10F-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

G10018 |

12/10ST-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

FAM12018 |

14/12F-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

G12018 |

14/12ST-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

H14018 |

16/14TU-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

|

U18018 |

20/18TU-AH |

R55, R33, R26, S42, S12, S31, S45, S51 |

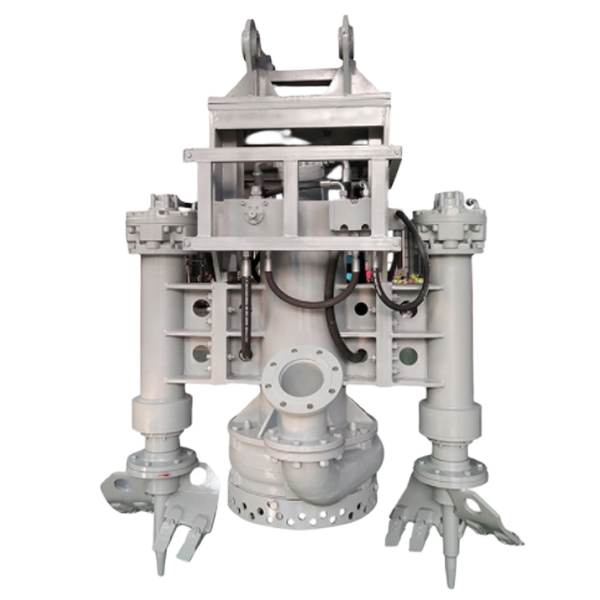

Rubber Lined Slurry Pumps Applications

Mining & Mineral Processing

The slow running speeds of the Ruite heavy duty rubber lined slurry pump, together with the comprehensive choice of abrasion resistant alloys and elastomers, provide unrivalled performance and service life for all abrasive mining and minerals processing applications.

Sand & Gravel

Designed for easy and simple strip down and re-assembly, the Ruite heavy duty rubber lined slurry pump minimises downtime, making it the ideal choice where installed stand by pumps are not available.

Sugar Processing

The premium reliability and service life of the Ruite heavy duty rubber lined slurry pump is specified by many sugar plant engineers worldwide where uninterrupted pump operation during the sugar campaign is a critical requirement.

Flue Gas Desulphurisation

The new generation of specially formulated abrasion and corrosion resistant alloys, together with the very latest elastomer technology, positions Ruite Pumps firmly as a major supplier of pumps to the FGD industry.

Industrial Applications

Wherever abrasive solids are causing premature failure of pumps, the Ruite heavy duty rubber lined slurry pump range has the right combination of performance, wear life and reliability to bring the customer the lowest cost of ownership.

Product detail pictures:

Related Product Guide:

We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Renewable Design for Slurry Booster Pump - Rubber Cover Pate Liner – Ruite Pump , The product will supply to all over the world, such as: Malawi, Atlanta, Russia, We will supply much better products with diversified designs and professional services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

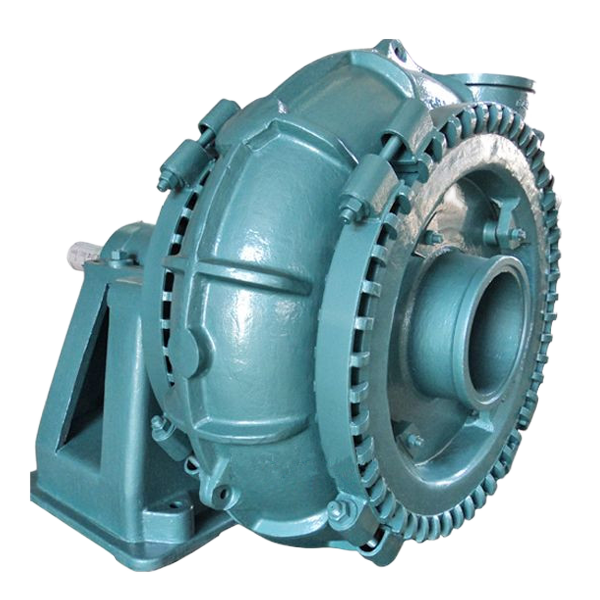

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!