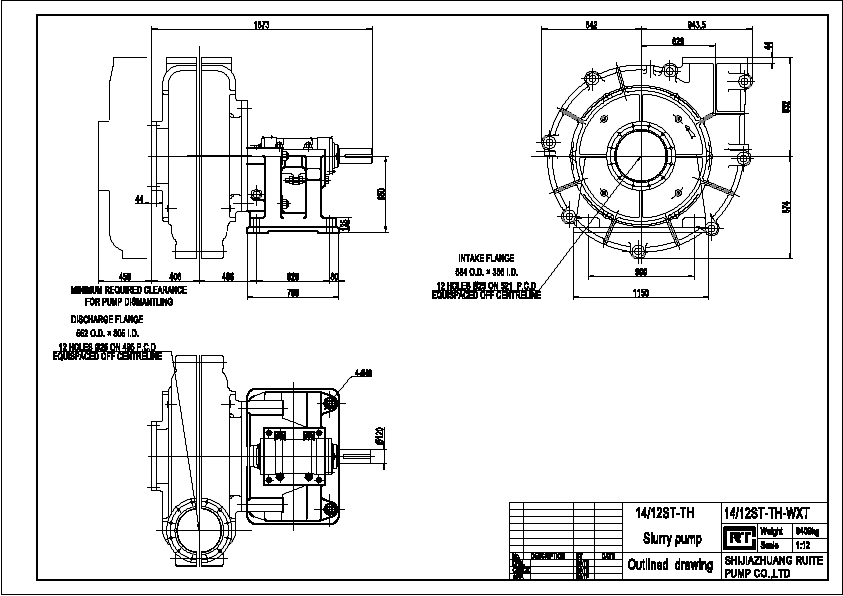

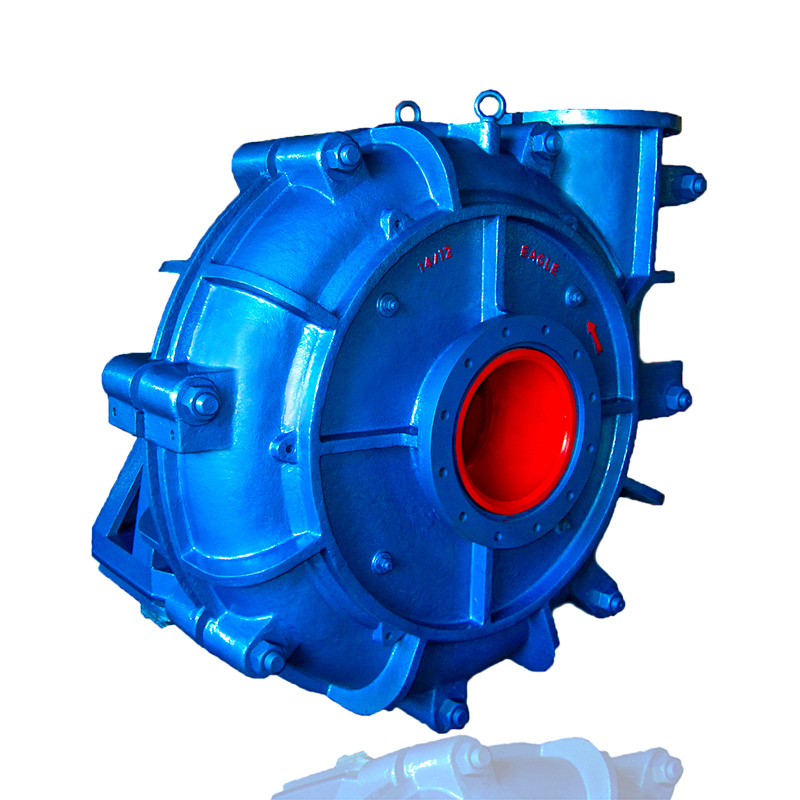

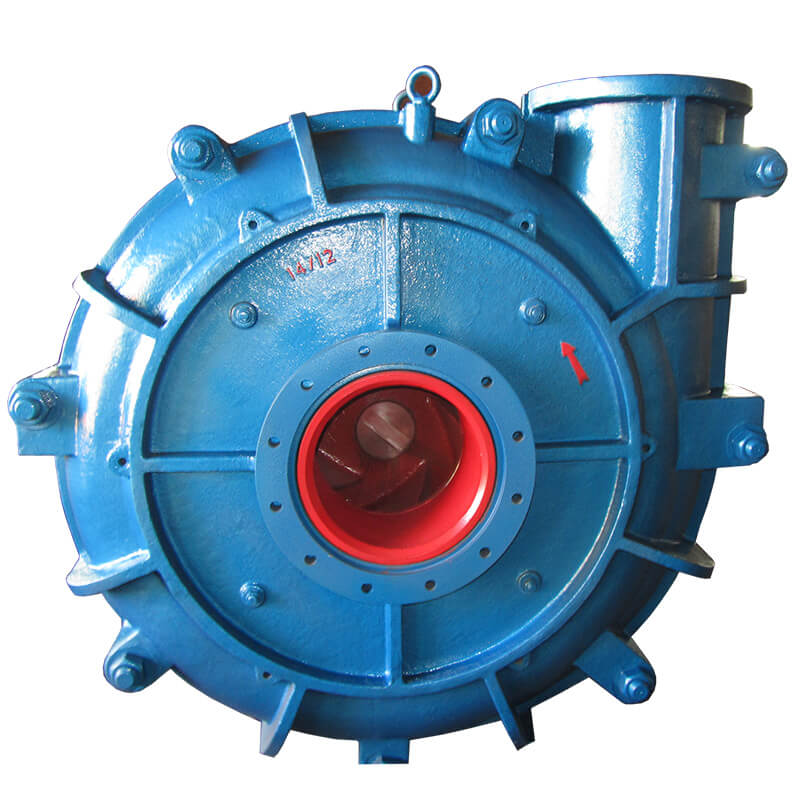

Quality Inspection for High Chrome Slurry Pump - 14/12 ST-TH Slurry Pump Supplier From China – Ruite Pump

Quality Inspection for High Chrome Slurry Pump - 14/12 ST-TH Slurry Pump Supplier From China – Ruite Pump Detail:

Description

TH series are single-stage, single-suction, cantilever, double-shell, horizontal centrifugal slurry pumps.They are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries for Conveying strong corrosive, high-concentrative slurries.Especially suitable for a variety of harsh working conditions, it is the first choice for the transportation of mine mill slurry and tailings slurry.They are mainly used for mill underflow, cyclone feeding, flotation, tailings efflux, sand removal, dredging, FGD, heavy media, ash removal, etc.

Diameter: 25mm~450mm

Power: 0-2000kw

Flow rate: 0~5400㎥/h

Head: 0~128m

Speed: 0~3600rpm

Material: high chrome alloy or rubber

TH(R) Slurry Pump Water Performance Curve

Application

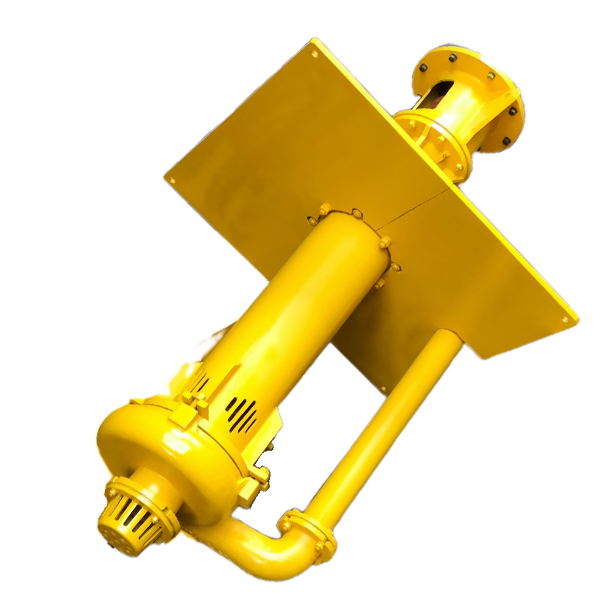

1、Centrifugal slurry pumps can have between bearing-supported shafts with split casing or rubber- or metal-lined casing. Configurations include horizontal, vertical suspended and submersible.

2、Before selecting an appropriate slurry pump the engineers considers capacity, head, solids handling capacity, efficiency and power, speed and NPSH.

Shijiazhuang Ruite Pump Co.Ltd

Abrasion Resistant Solid Handling Centrifugal Sand Washing Slurry Pump

TH series Centrifugal Horizontal Heavy Duty Slurry Pumps are designed for handling highly abrasive,high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

Feature

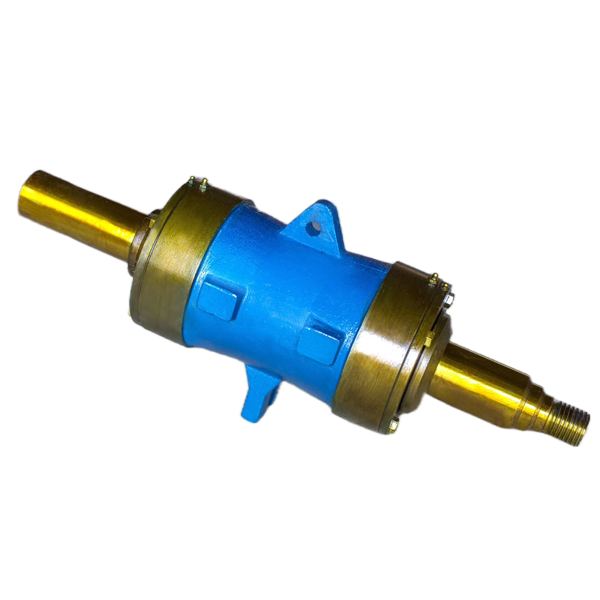

1. Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner and can be removed completely;

2. Anti-abrasion wet parts: The wet parts can be made of pressure molded rubber. They are completely interchangeable with metal wet parts.

3. The discharge branch can be oriented to any eight positions at the interval of 45 degrees;

4. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc;

5. The shaft seal uses the packing seal, expeller seal and mechanical seal;

Over view

RT High Chrome Alloy Slurry Pumps are single-stage,single-suction and cantilevered, double casing, horizontal, centrifugal ,heavy duty durable design

Parts in contacting with the medium are made of latest wear-resistance 27% chrome alloy white iron with hardness 62HRC over

which has an highly abrasive for maximum resistance to strong abrasive, coarse particle.

They are widely used for mining, coal, metallurgical, power, building material and other industrial departments. This series of pump

is suitable for various liguids performance, which is the first select product for handling mine mill slurry and tailing slurry

Basing on medium condition can choose different materials as A05.A07.A49 etc.

The Process Flow

Texture Profile

More Details

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our management ideal for Quality Inspection for High Chrome Slurry Pump - 14/12 ST-TH Slurry Pump Supplier From China – Ruite Pump , The product will supply to all over the world, such as: Wellington, Johor, Lisbon, Our products are produced with the best raw materials. Every moment, we constantly improve the production programme. In order to ensure better quality and service, we have been focusing on the production process. We have got high praise by partner. We are looking forward to establishing business relationship with you.

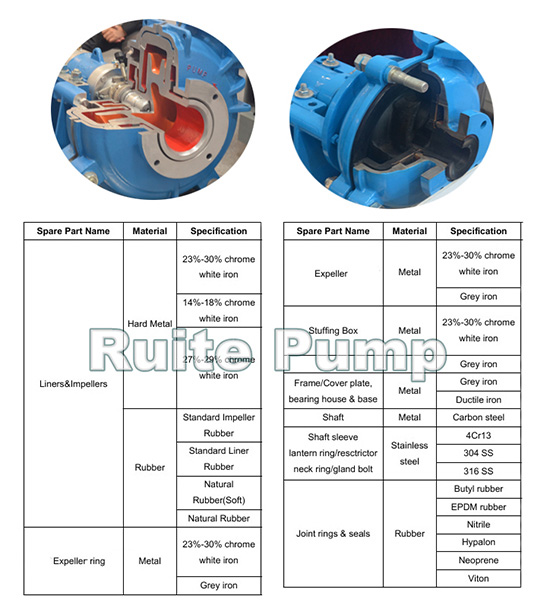

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

We have worked with many companies, but this time is the best,detailed explanation, timely delivery and quality qualified, nice!