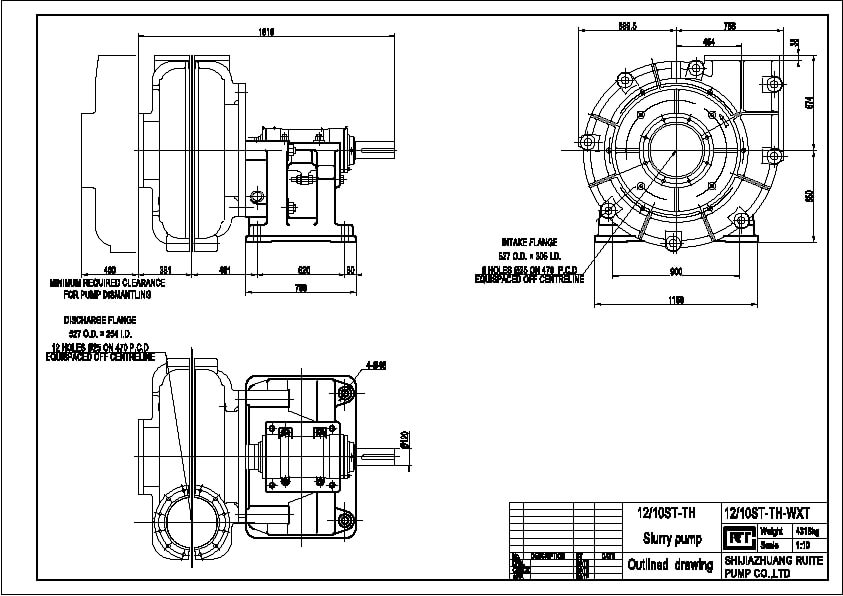

PriceList for Sump Slurry Pumps With Agitator - 12/10 ST-TH Horizontal Slurry Pump, Factory outlet from China – Ruite Pump

PriceList for Sump Slurry Pumps With Agitator - 12/10 ST-TH Horizontal Slurry Pump, Factory outlet from China – Ruite Pump Detail:

Description

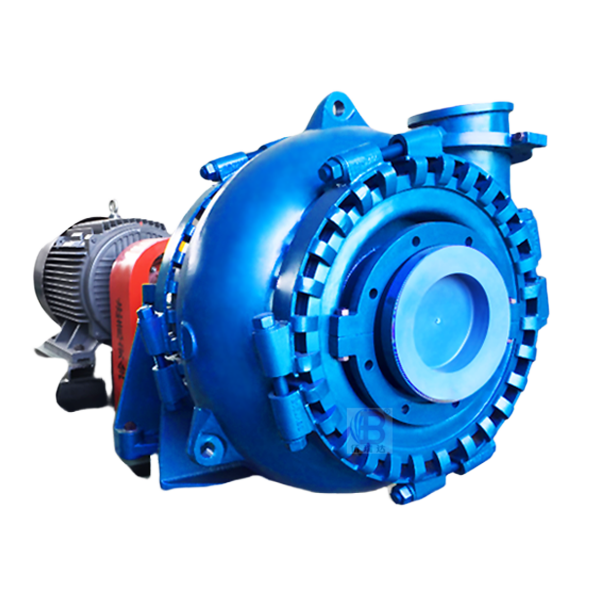

TH series are single-stage, single-suction, cantilever, double-shell, horizontal centrifugal slurry pumps.They are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries for Conveying strong corrosive, high-concentrative slurries.Especially suitable for a variety of harsh working conditions, it is the first choice for the transportation of mine mill slurry and tailings slurry.They are mainly used for mill underflow, cyclone feeding, flotation, tailings efflux, sand removal, dredging, FGD, heavy media, ash removal, etc.

Diameter: 25mm~450mm

Power: 0-2000kw

Flow rate: 0~5400㎥/h

Head: 0~128m

Speed: 0~3600rpm

Material: high chrome alloy or rubber

TH(R) Slurry Pump Water Performance Curve

What Are Slurries

Slurries are mixtures of solids and liquids, with the liquid serving as the transport mechanism used to move the solid. The size of the particles (or solids) in slurries ranges from one micron in diameter up to hundreds of millimeters in diameter. The particle size significantly impacts a pump’s ability to move a slurry through a process line.

All slurries share five essential characteristics:

. More abrasive than pure liquids.

. Thicker in consistency than pure liquids.

. May contain a high number of solids (measured as a percentage of the total volume).

. The solid particles usually settle out of the slurry’s precipitate relatively quickly when not in motion (depending on the particle size).

. Slurries require more energy to move than do pure liquids.

Shijiazhuang Ruite Pump Co.Ltd

Abrasion Resistant Solid Handling Centrifugal Sand Washing Slurry Pump

TH series Centrifugal Horizontal Heavy Duty Slurry Pumps are designed for handling highly abrasive,high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

Feature

1. Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner and can be removed completely;

2. Anti-abrasion wet parts: The wet parts can be made of pressure molded rubber. They are completely interchangeable with metal wet parts.

3. The discharge branch can be oriented to any eight positions at the interval of 45 degrees;

4. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc;

5. The shaft seal uses the packing seal, expeller seal and mechanical seal;

The Process Flow

Texture Profile

More Details

About Ruite

1.Ruite is a leading Chinese pump manufacturer and devoted to offering professional slurry pump solutions for you. We have successfully undertaken many projects in over 40 countries. Innovative R&D department and state-of-art technology are the basis of Excellence high quality products. Scientific model selection and slurry transporting solution helps to reduce your purchase and maintenance cost. Above all, all-around services will save you a lot of effort and it will be a enjoyable experience.

2.Ruite Pump Industry Co., Ltd. is devoting to offering the best slurry pump solution around the world. With years of accumulation and development, we have formed a complete system of slurry pump production, design, selection, application and maintenance. Our products are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries. Thanks to the trust and recognition of our clients from over 40 countries, we are becoming one of the most important slurry pump suppliers in China.

3.Ruite production line includes four major procedures strictly supervised by our quality control personnel, including foundry, machining, assembling and testing.

4.Ruite has well-developed QC department.

5.Quality control file:

6.Records of quality control process: casing test record, semi-finished product inspection, processing inspection, assembly inspection, pressure testing record, spray paint inspection, motor packing inspection, shipping list;

Product detail pictures:

Related Product Guide:

We now have our own gross sales team, style and design workforce, technical crew, QC workforce and package group. We now have strict quality manage procedures for each system. Also, all of our workers are experienced in printing industry for PriceList for Sump Slurry Pumps With Agitator - 12/10 ST-TH Horizontal Slurry Pump, Factory outlet from China – Ruite Pump , The product will supply to all over the world, such as: Germany, Chicago, Slovenia, Our company insists on the purpose of "takes service priority for standard, quality guarantee for the brand, do business in good faith, to offer skilled, rapid, accurate and timely service for you". We welcome old and new customers to negotiate with us. We are going to serve you with all sincerity!

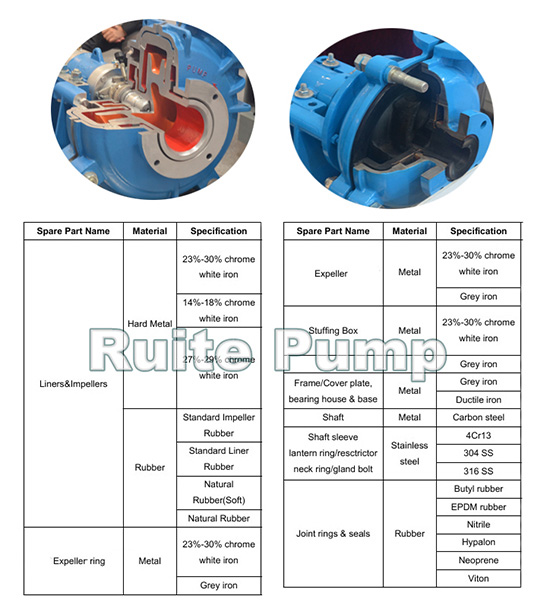

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.