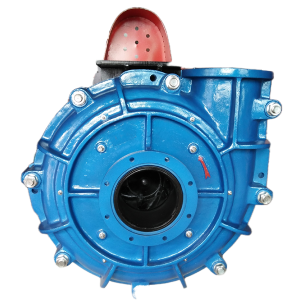

OEM/ODM China Heavy Duty Anti Wear Centrifugal Slurry Pump

owing to fantastic assistance, a variety of high quality goods, aggressive rates and efficient delivery, we love a very good popularity among our customers. We are an energetic firm with wide market for OEM/ODM China Heavy Duty Anti Wear Centrifugal Slurry Pump, Customers first! Whatever you require, we should do our utmost to help you. We warmly welcome customers from all over the world to cooperate with us for mutual development.

owing to fantastic assistance, a variety of high quality goods, aggressive rates and efficient delivery, we love a very good popularity among our customers. We are an energetic firm with wide market for China Lurry Pump for Mining and Mining Feeding Pump, Our objective is “to supply first step products and solutions and best service for our customers, thus we’re sure you will have to have a margin benefit through cooperating with us”. If you are interested in any of our merchandise or would like to discuss a custom order, please feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.

4/3C-THR Rubber lined Slurry Pump is widely used for transporting slurry with strong corrosion and high concentration for many industries such as metallurgy,mine,coal,electric power,building materials etc.The wet parts is 100%interchangeable with 4/3C-AH metal lined slurry pump.

Design Features:

√Bearing assembly:large diameter shaft with short overhang contributes to long bearing life.

√Liners:Easily replaceable liners are bolted,not glued to the casing for positive maintenance.

√Casing:Casing halves of cast or ductile iron provide high operating pressure capabilities.

√Impeller:Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

√Throatbush:Wear is reduced and maintenance simplified by the use of tapered.

4/3 C THR Rubber Lined Slurry Pump Performance Parameters:

|

Model |

Max. Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q (m3/h) |

Head H (m) |

Speed n (rpm) |

Eff. η (%) |

NPSH (m) |

|||

|

4/3C-AHR |

30 |

Rubber |

Rubber |

79.2-180 |

5-34.5 |

800-1800 |

59 |

3-5 |

5 |

Rubber Lined Slurry Pumps Applications:

Rubber lined slurry pumps are widely used for wet crushers,SAG mill discharge,ball mill discharge,rod mill discharge,Ni acid slurry,coarse sand,coarse tailings,phosphate matrix,minerals concentrate,heavy media,dredging,bottom/fly ash,lime grinding,oil sands,mineral sands,fine tailings,phosphoric acid,coal,flotation,sugar beets,process chemical,pulp and paper,FGD,waste water etc.

Note:

4/3 C THR rubber lined slurry pumps and parts are only interchangeable with Warman®4/3 C THR rubber lined slurry pumps and parts.owing to fantastic assistance, a variety of high quality goods, aggressive rates and efficient delivery, we love a very good popularity among our customers. We are an energetic firm with wide market for OEM/ODM China Heavy Duty Anti Wear Centrifugal Slurry Pump, Customers first! Whatever you require, we should do our utmost to help you. We warmly welcome customers from all over the world to cooperate with us for mutual development.

OEM/ODM China China Lurry Pump for Mining and Mining Feeding Pump, Our objective is “to supply first step products and solutions and best service for our customers, thus we’re sure you will have to have a margin benefit through cooperating with us”. If you are interested in any of our merchandise or would like to discuss a custom order, please feel free to contact us. We’re looking forward to forming successful business relationships with new clients around the world in the near future.

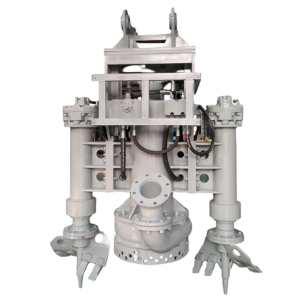

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |