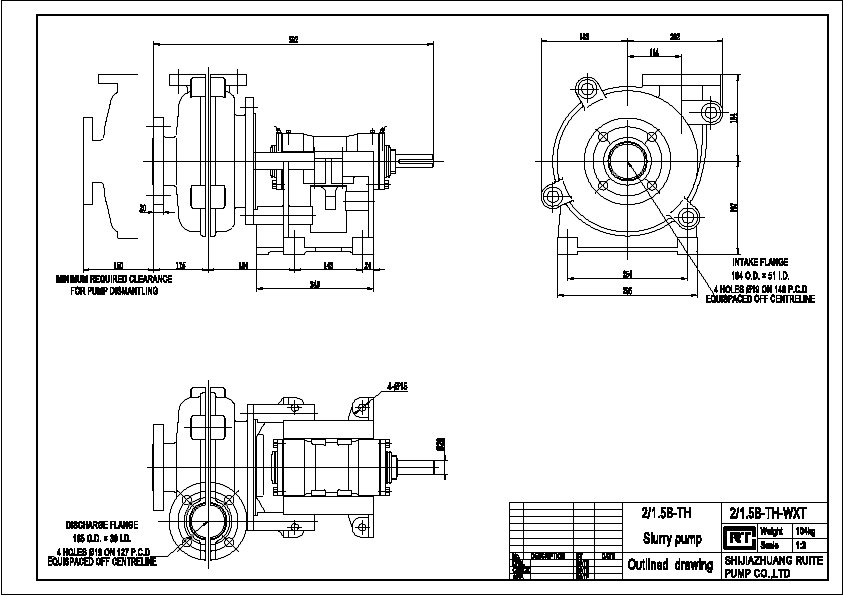

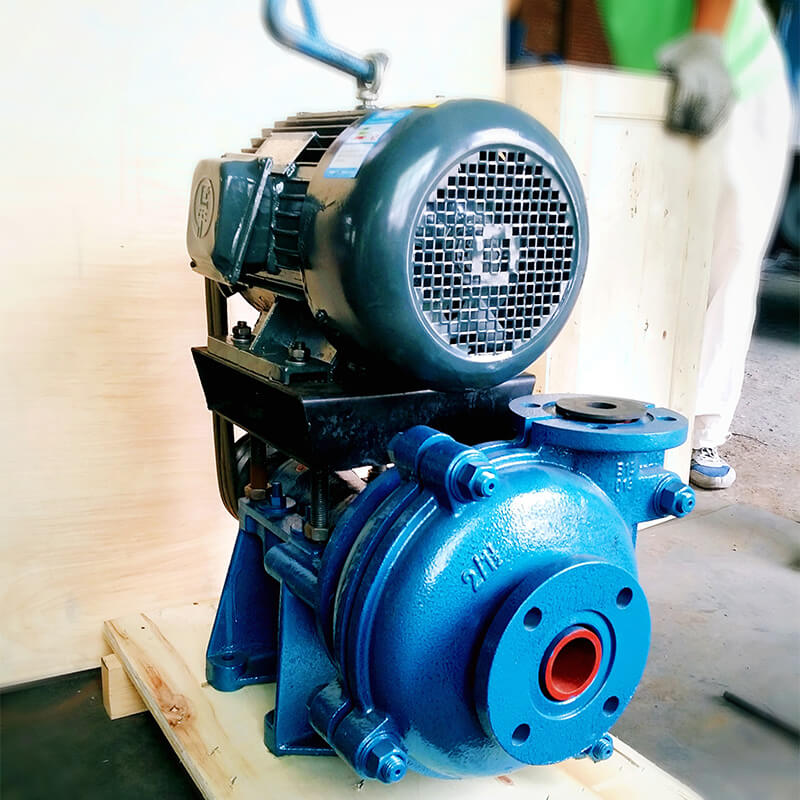

OEM Factory for Sewage Slurry Mud Pump - 2/1.5B-TH small Slurry Pump Manufacturer – Ruite Pump

OEM Factory for Sewage Slurry Mud Pump - 2/1.5B-TH small Slurry Pump Manufacturer – Ruite Pump Detail:

Description

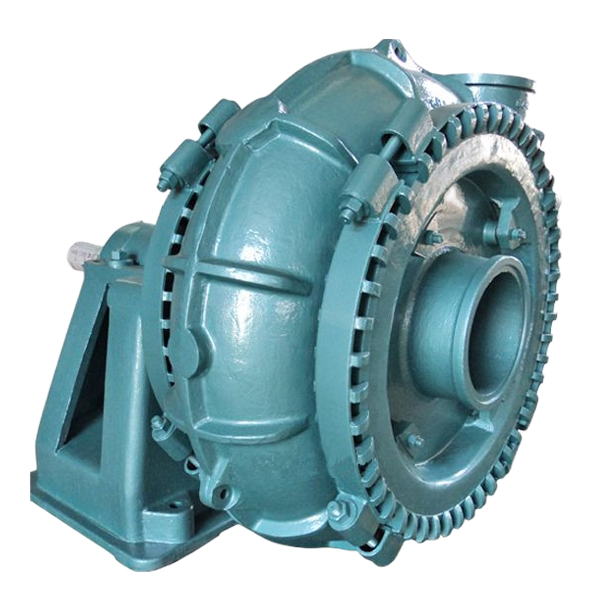

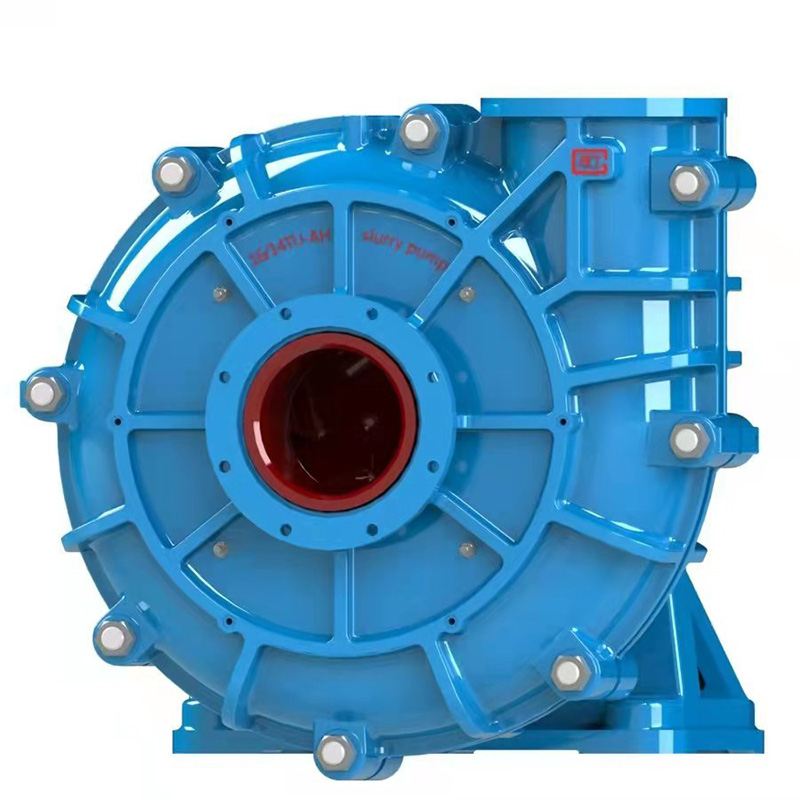

TH series are single-stage, single-suction, cantilever, double-shell, horizontal centrifugal slurry pumps.They are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries for Conveying strong corrosive, high-concentrative slurries.Especially suitable for a variety of harsh working conditions, it is the first choice for the transportation of mine mill slurry and tailings slurry.They are mainly used for mill underflow, cyclone feeding, flotation, tailings efflux, sand removal, dredging, FGD, heavy media, ash removal, etc.

Diameter: 25mm~450mm

Power: 0-2000kw

Flow rate: 0~5400㎥/h

Head: 0~128m

Speed: 0~3600rpm

Material: high chrome alloy or rubber

TH(R) Slurry Pump Water Performance Curve

Application

Slurry pumps are widely used in transport of abrasive solids in industries such as mining, dredging, and steel. They are often designed to be suitable for heavy-wearing and heavy-duty uses. Depending on the mining process, some slurries are corrosive which presents a challenge because corrosion-resistant materials like stainless steel are softer than high-iron steel. The most common metal alloy used to build slurry pumps is known as “high chrome”, which is basically white iron with 25%-27% chromium added to make it less brittle. Rubber line casings are also used for certain application where the solid particles are small.

Shijiazhuang Ruite Pump Co.Ltd

Abrasion Resistant Solid Handling Centrifugal Sand Washing Slurry Pump

TH series Centrifugal Horizontal Heavy Duty Slurry Pumps are designed for handling highly abrasive,high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

Feature

1. Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner and can be removed completely;

2. Anti-abrasion wet parts: The wet parts can be made of pressure molded rubber. They are completely interchangeable with metal wet parts.

3. The discharge branch can be oriented to any eight positions at the interval of 45 degrees;

4. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc;

5. The shaft seal uses the packing seal, expeller seal and mechanical seal;

The Process Flow

Texture Profile

More Details

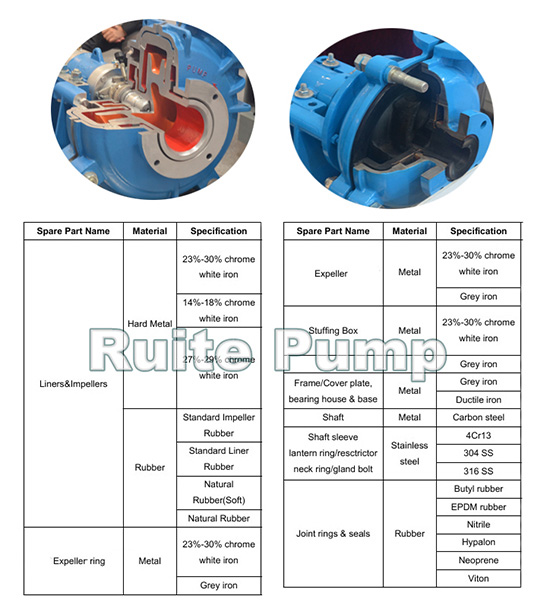

Accessories Description

TH Slurry Pumps are designed for handling highly abrasive,high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

At present, Ruite has the new material MC01, MC01 spares part service life is 1.5-2 times than A05 material.

Our production ability 1200ton per month,The largest wear-resistant casting weighs can up to 12 ton. Welcome to visit.thank you

Principle

1.Slurry pumps are typically larger in size than standard pumps, with more horsepower, and built with more rugged bearings and shafts. The most common type of slurry pump is the centrifugal pump. These pumps use a rotating impeller to move the slurry, similar to how a water-like liquid would move through a standard centrifugal pump.

2.Centrifugal pumps optimized for slurry pumping will generally feature the following in comparison to standard centrifugal pumps:

Larger impellers made with more material. This is to compensate for wear caused by abrasive slurries.

Fewer, thicker vanes on the impeller. This allows the passage of solids more readily — typically 2-5 vanes, compared to 5-9 vanes on a standard centrifugal pump.

3.The corrosiveness of the liquid or slurry mixture: more corrosive slurries will wear pump components more quickly and may dictate the selection of the material from which the pump is constructed.

4.The size and nature of the solids in the liquid: the size and nature will affect the amount of physical wear on the pump and its components .

Product detail pictures:

Related Product Guide:

Which has a positive and progressive attitude to customer's desire, our corporation constantly improves our merchandise quality to satisfy the desires of consumers and further focuses on safety, reliability, environmental demands, and innovation of OEM Factory for Sewage Slurry Mud Pump - 2/1.5B-TH small Slurry Pump Manufacturer – Ruite Pump , The product will supply to all over the world, such as: Marseille, Danish, Monaco, Upon today, we have customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We are looking forward to doing business with you.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.