OEM Customized Electric Slurry Pump - TGQ Submersible Gravel Pump – Ruite Pump

OEM Customized Electric Slurry Pump - TGQ Submersible Gravel Pump – Ruite Pump Detail:

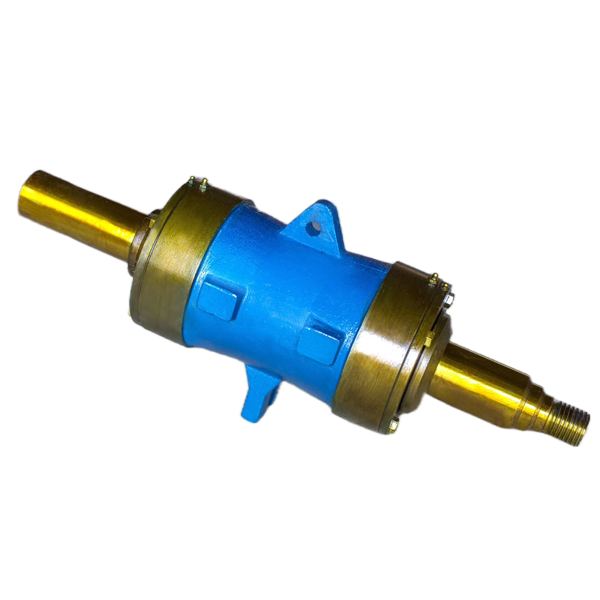

Durable, electro-submersible Gravel pump. Versatile and rugged solution for the transfer of abrasive and high density slurries on mining, civil construction, inrustry and otherheavy duty applications.

The pump casing features a large clearance which allows the easy passage of large solids and reduces wear and erosion to improve service life and prevent loss of efficiency.

TGQ series heavy duty submersible Gravel pump is designed and suitable for conveying liquid with slurry, big solid particles of gravel, cinders, tailings, etc.

This heavy duty submersible dredge pumps are commonly used in applications as river dredging, sand pumping vessel, sewage treatment plants, metallurgical industry, mining, power plants, etc.

Features

HEAVY DUTY CONSTRUCTION

The pump casing, impeller, back plate and agitator are manufactured from high quality 27% chrome white iron.

This extremely tough construction material can withstand continuous use in heavy duty applications and allows the pumps to transfer abrasive and dense slurries with minimal wear. The pumps feature a replaceable back plate allowing for simple servicing and easy replacement of worn components.

INTEGRAL AGITATOR

The 27% chrome white iron agitator assists in the pumping of slurries by breaking up large particles and agitating, high concentrations of solids

Wet wear parts are all constructed with abrasion resistant chromium alloy which hardness is more than 58HRC with strong anti-attack, resistance wear and abrasion.

TGQ Submersible Sand Pumps Applications:

TGQ Submersible Sand Pump widely used for Dredging, Ocean Sand mining, ponds, Fly ash/ bottom ash, Sand and Gravel excavation, Hazardous waste clean-up, Tank clean up (replacing vacuum trucks), Cleaning out numerous sumps including at: Cement plants, Agricultural wash down pits (carrots, beats etc), Pipeline burial, Coke pits, Mill scale/ slag pits, Barge unloading, Silt removal, Removal of filer media at waste treatment plants, Island building etc.

Product detail pictures:

Related Product Guide:

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for OEM Customized Electric Slurry Pump - TGQ Submersible Gravel Pump – Ruite Pump , The product will supply to all over the world, such as: Wellington, French, Muscat, We welcome customers from all over the world come to discuss business. We supply high quality solutions, reasonable prices and good services. We hope to sincerely build business relationships with customers from at home and abroad, jointly striving for a resplendent tomorrow.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.