In the operation of slurry pumps, the periodic adjustment of impeller clearance throughout its operating life plays a crucial role in maximizing the wear life of both the impeller and the front liner. This aspect cannot be overlooked as it has a significant impact on the overall performance and longevity of the slurry pump.

Extensive field experience has provided valuable insights in this regard. It has been demonstrated that by conducting regular impeller adjustments, a remarkable increase in wear life can be achieved. Compared to pumps that do not undergo any initial or ongoing adjustment, the wear life can be boosted by up to 50 percent. Moreover, when compared to pumps that are only subjected to an initial adjustment, regular impeller adjustment typically leads to a 20 percent increase in wear life. This clearly highlights the importance of consistent attention to impeller clearance over time.

The recommended procedure for carrying out periodic impeller adjustment in slurry pumps is as follows:

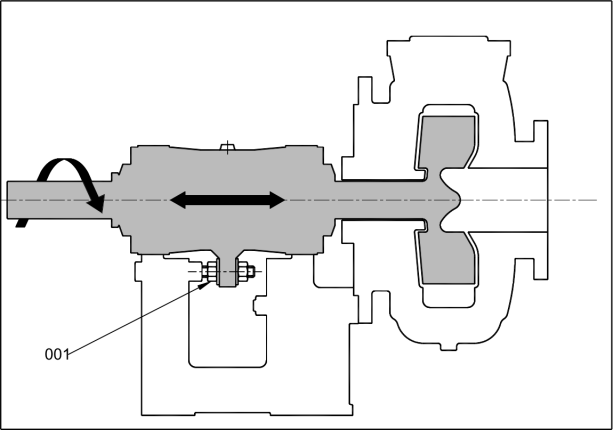

Firstly, during the initial pump assembly of the slurry pump, it is essential to adjust the impeller to “just clear” the throatbush or the front liner. This initial setup is a fundamental step and lays the foundation for proper operation and wear management.

Secondly, after the slurry pump has been in operation for 50 to 100 hours, it is necessary to re-adjust the impeller front-end clearance. This timely readjustment accounts for the initial wear and settling that occurs during the early stages of operation and helps maintain optimal performance.

Thirdly, over the wear life of the impeller, it should be re-adjusted at the front-end clearance a further two or three times at regular intervals. These intervals often coincide with the regular pump maintenance schedules, which are typically around 500 hours. This consistent maintenance approach ensures that the impeller continues to operate within the desired clearance range, minimizing excessive wear and maximizing its lifespan.

It is important to note that after each impeller adjustment is completed in the slurry pump, the BEARING HOUSING CLAMP BOLTS must be tightened to the torque values indicated in Table 5 (below). In case a torque wrench or an equivalent device is not available, the bolts should still be tightened as carefully as possible to ensure the stability and proper functioning of the pump. By following these procedures meticulously, the slurry pump can operate more efficiently and have an extended wear life for its critical components like the impeller and front liner.

To get more information about the slurry pump impeller adjustment, please send email or whatsapp Rita as below shows:

email: rita@ruitepump.com

whatsapp: +8619933139867

web: www.ruitepumps.com

Post time: Dec-26-2024