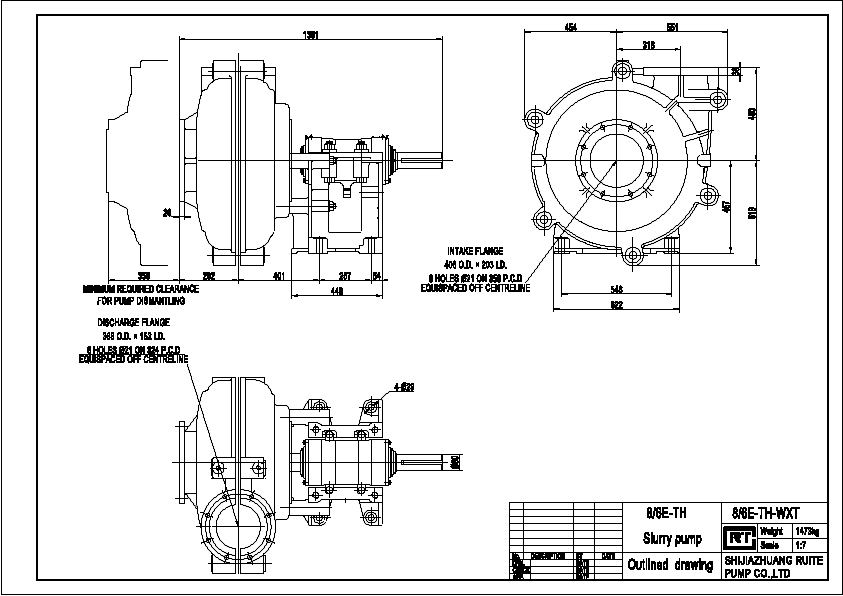

New Delivery for Progressive Cavity Pump For Slurry - Horizontal 8-6E-TH heavy duty Slurry Pump Manufacturer from china – Ruite Pump

New Delivery for Progressive Cavity Pump For Slurry - Horizontal 8-6E-TH heavy duty Slurry Pump Manufacturer from china – Ruite Pump Detail:

Description

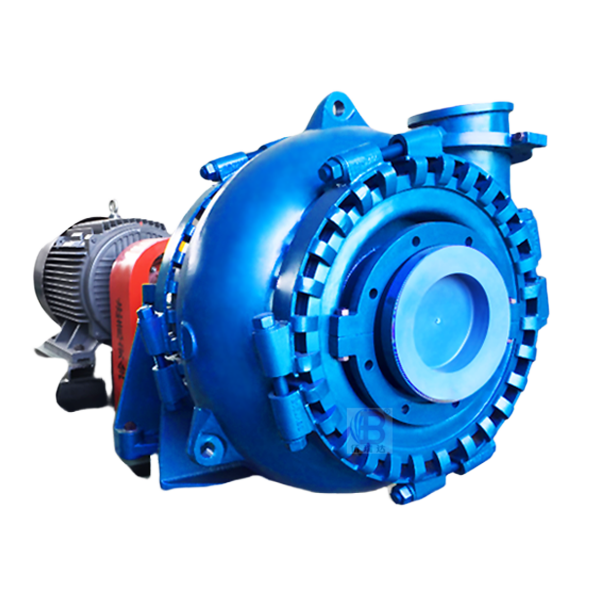

TH series are single-stage, single-suction, cantilever, double-shell, horizontal centrifugal slurry pumps.They are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries for Conveying strong corrosive, high-concentrative slurries.Especially suitable for a variety of harsh working conditions, it is the first choice for the transportation of mine mill slurry and tailings slurry.They are mainly used for mill underflow, cyclone feeding, flotation, tailings efflux, sand removal, dredging, FGD, heavy media, ash removal, etc.

Diameter: 25mm~450mm

Power: 0-2000kw

Flow rate: 0~5400㎥/h

Head: 0~128m

Speed: 0~3600rpm

Material: high chrome alloy or rubber

TH(R) Slurry Pump Water Performance Curve

Components

Impeller

The impeller, either elastomer, stainless steel or high-chrome material, is the main rotating component which normally has vanes to impart the centrifugal force to the liquid.

Casing

Split outer casing halves of cast contain the wear liners and provide high operation pressure capabilities. The casing shape is generally of semi-volute or concentric, efficiencies of which are less than that of the volute type.

Shaft and Bearing Assembly

A large diameter shaft with a short overhang minimizes deflection and vibration. Heavy-duty roller bearing are housed in a removable bearing cartridge.

Shaft sleeve

A hardened, heavy-duty corrosion-resistant sleeve with O-ring seals at both ends protects the shaft. A split fit allows the sleeve removed or installed quickly.

Shaft Seal

Expeller drive seal, Packing seal, Mechanical seal.

Drive Type

V-belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices.

Shijiazhuang Ruite Pump Co.Ltd

Abrasion Resistant Solid Handling Centrifugal Sand Washing Slurry Pump

TH series Centrifugal Horizontal Heavy Duty Slurry Pumps are designed for handling highly abrasive,high density slurries with excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost.

Feature

1. Cylindrical structure of bearing assembly: convenient to adjust the space between impeller and front liner and can be removed completely;

2. Anti-abrasion wet parts: The wet parts can be made of pressure molded rubber. They are completely interchangeable with metal wet parts.

3. The discharge branch can be oriented to any eight positions at the interval of 45 degrees;

4. Various drive types: DC(direct connection), V-belt drive, gear box reducer, hydraulic couplings, VFD, SCR control, etc;

5. The shaft seal uses the packing seal, expeller seal and mechanical seal;

Structure

A centrifugal heavy duty alloy liner mine tailing slurry pump is mainly composed of 3 parts?

1.The anti-abrasion wet parts:(lmpeller.Throatbush. Volute liner. FPL insert) Thickened wet components for extended wear life.

2.Shaft seal parts: Sealing flexibility choice of aland. Expeller seal or mechanical seals.

3. Bearing assembly parts

Bearing assembly-Alarge diameter shaft with short overhang minimizes deflection and contributes to long bearing life.Only four through bolts are required to hold the cartridge type housing in the frame.

The removable cartridge-type bearing assembly facilitates easy on-site maintenance procedures

The Process Flow

Texture Profile

More Details

Product detail pictures:

Related Product Guide:

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for New Delivery for Progressive Cavity Pump For Slurry - Horizontal 8-6E-TH heavy duty Slurry Pump Manufacturer from china – Ruite Pump , The product will supply to all over the world, such as: Korea, Madagascar, Swaziland, With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

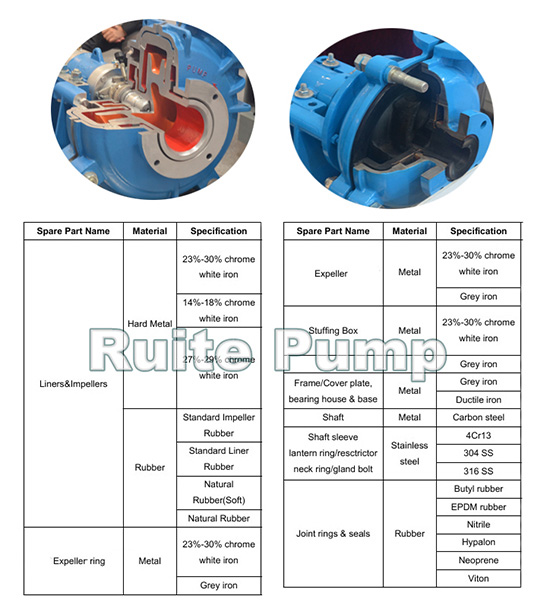

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!