Marine Double-Walled 900WN Dredge Pump

WN dredge pump is a single-stage single suction cantilever horizontal centrifugal pump, with light weight, good-resistance, super dreding performance, perfectly suited for the dredge on the whole construction, high multiple economy benefits, etc. They can meet all the requirements from the dredges. Dredge pump are specially designed for mud, sand dredging application in river or sea. Robust structure design with front disassemble way guarantee its extra long work life and easily maintenance.

300WN~500WN with single shell structure and 600WN~1000WN double shell structure to satisfy heavy duty dredging work. High chrome alloy made liner spares with a hardness 60HRC could bear severe bear and tear.

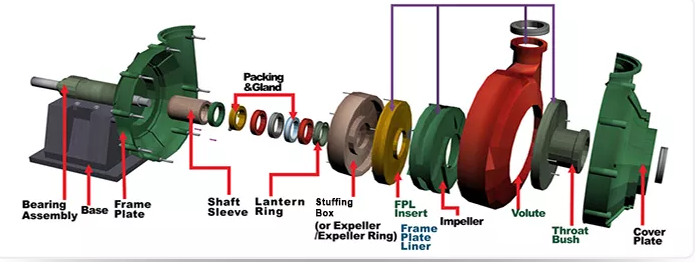

- WN series dredge pump Structure

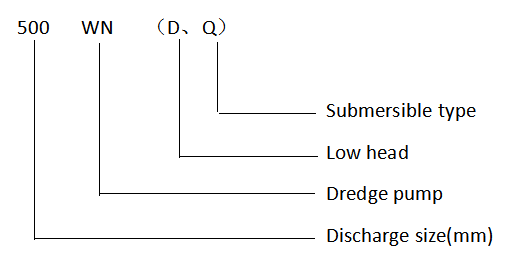

- Dredge Pump Model Sense

- Dredge Pump Performance Data

Model Capacity

m3/hHead

mSpeed

r/minNPSHr m Inlet Diametermm Outlet Diametermm Max Dia of Particle mm 900WN(Q) 12000-19000 20-75 180-350 <6 960 900 320

- Dredge Pump Feature

1.The whole construction is suitable for dredging ship

2.Reliable and simple structure(200WN~500WN type is single casing pump,600WN~1000WN is double casing pump)

3.Easy disassembly and installation, convenient maintenance

4.Dredging performance is excellent,

5.good NPSH, strong through-put capability

6.The curve of performance decrease sharply, to make the pump more adaptive in the change of discharge distance.

7.Pump performance can be in a variety of change.

8.Excellent ant-wear performance, long service of wet parts

9.A little hydraulic loss, high efficiency, low consumption

10.Reliable shaft sealing without leakage

11.Drive type: Generally use belt driven or Gear transmission

- Dredge Pump Application example

- Dredge Pump Package and Shipping

For more information about our Dredge pump, please contact us freely.

Email: rita@ruitepump.com

Whatsapp/Wechat: +8619933139867

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |