Manufacturing Companies for Heavy Duty Slurry Pumps for Mill Discharge & Process Plant

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Manufacturing Companies for Heavy Duty Slurry Pumps for Mill Discharge & Process Plant, High quality would be the key factor for that organization to stand out from other competitors. Seeing is Believing, want more information? Just trial on its items!

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for China Mill Discharge Slurry Pump and Process Plant Pump, You can always find the solutions you require in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We’re looking forward to work with you for a win-win situation.

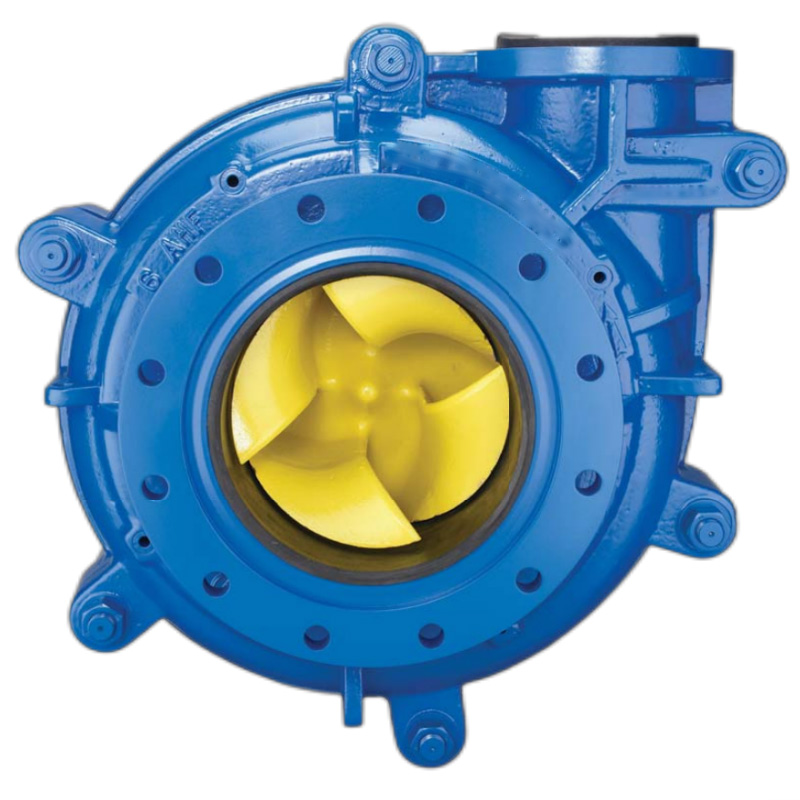

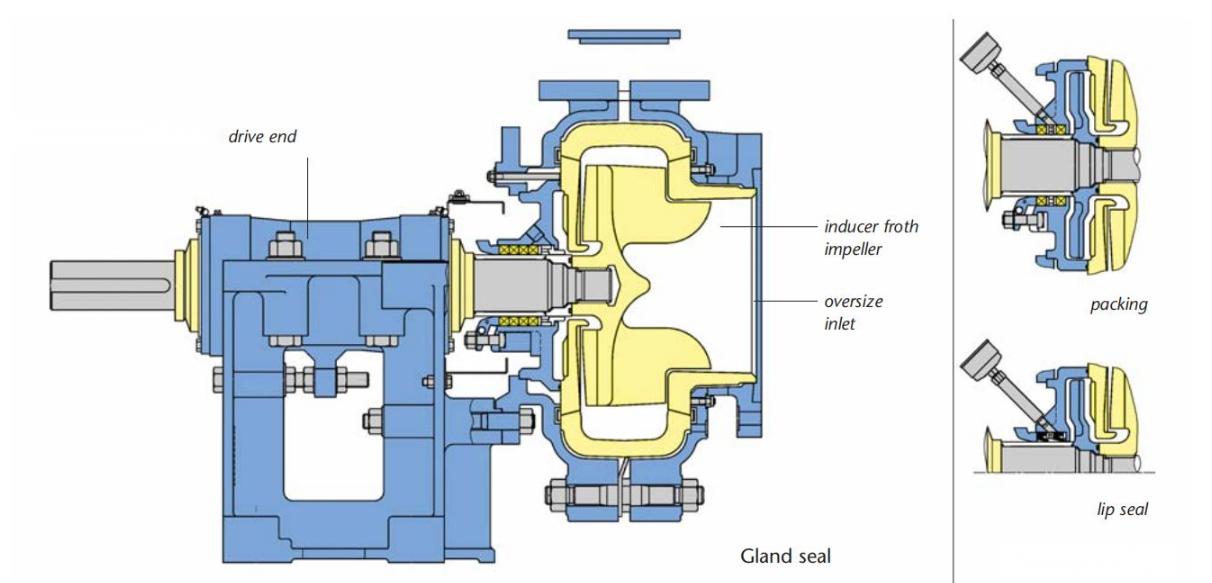

A large oversized inlet with a unique impeller inducer blade can easily handle heavy froth and higher viscosity dense slurry.

The semi-open metal impeller with screw compression function has a high head and is suitable for conveying high air content pulp.

Higher efficiency and lower energy consumption.

Features / Benefits

1.Size range (discharge) :2″ to 22″ (50 mm to 550 mm)

2.Capacities to:20,000 gpm (3,150 m3/hr)

3.Heads to: 120 ft (37 m)

4.Pressures to: 500 psi (3,445 kPa)With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Manufacturing Companies for Heavy Duty Slurry Pumps for Mill Discharge & Process Plant, High quality would be the key factor for that organization to stand out from other competitors. Seeing is Believing, want more information? Just trial on its items!

Manufacturing Companies for China Mill Discharge Slurry Pump and Process Plant Pump, You can always find the solutions you require in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We’re looking forward to work with you for a win-win situation.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |