Good Quality Sand And Gravel Pump - 8x6E-TG Gravel Pump, interchangeable with Warman pumps – Ruite Pump

Good Quality Sand And Gravel Pump - 8x6E-TG Gravel Pump, interchangeable with Warman pumps – Ruite Pump Detail:

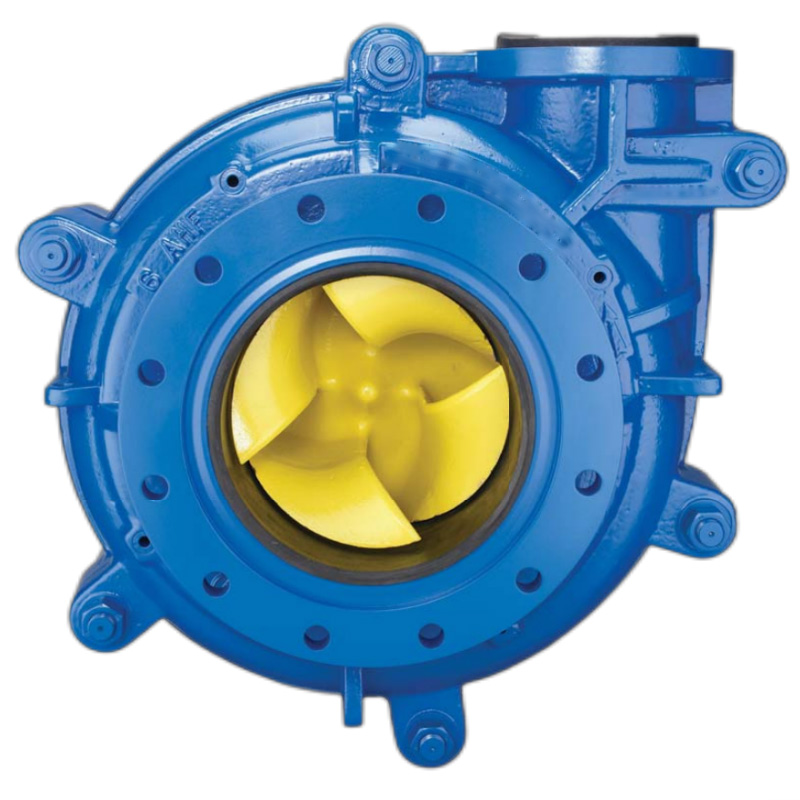

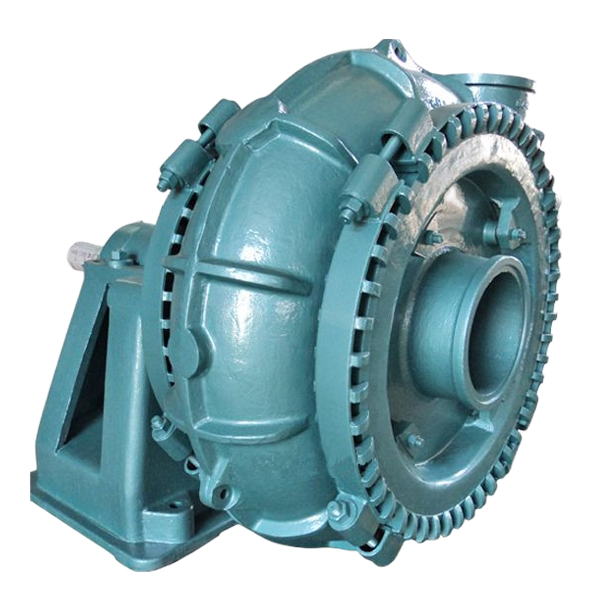

8x6E-TG Gravel Pump is suitable for handling large particles at consistently high efficiency, resulting in lower costs. Casing is designed with a large volume internal profile to reduce associated velocities which prolong component life. Designed to pump extremely aggressive slurries with a wide particle distribution, With a range of G series gravel parts and different material combinations Dredge and Gravel pumps have the versatility to ensure the most appropriate pumping solution can be provided for any given application.

Design Features

• The structure of TG series gravel pump is mainly single-casing and horizontal type, The outlet direction can be positioned 360°, easy to install.

• Shaft Components adopt cylinder structure, which is convenient to adjust the gap between impeller and front wearing plate, The shaft uses grease lubrication.

• Shaft Seal: packing seal, expeller seal and mechanical seal.

• Broad flow passage & good anti-Cavitation property & highly efficient wear resistance.

• The wet parts are made of Ni-hard and high-chrome wear-resistant alloys with good anti-corrosive property.

• Variable speeds and modals to ensure smooth operation, Additionally, Long service life and high operation efficiency offer reliable performance in a tough operating environment.

8/6E G Sand Gravel Pump Performance Parameter

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

8x6E-TG |

120 |

126-576 |

6-45 |

800-1400 |

60 |

3-4.5 |

391 |

8/6E-TG Gravel Pump Applications

| • Gravels | • Sands | • Dredging | • Sand Excavation |

| • Tunneling | • Tunnel boring machine | • Blast slag | • Dredger |

| • Pipe-jacking system | • Ash handing | • Coal ash | • Coarse sand |

| • Tailings | • Stone | • Waste sludge | • Mineral processing |

| • Mining | • Alumina Industry | • Construction | • Other industries |

Note:

8×6 E-TG gravel pumps and spares are only interchangeable with Warman® 8×6 E-G gravel pumps and spares.

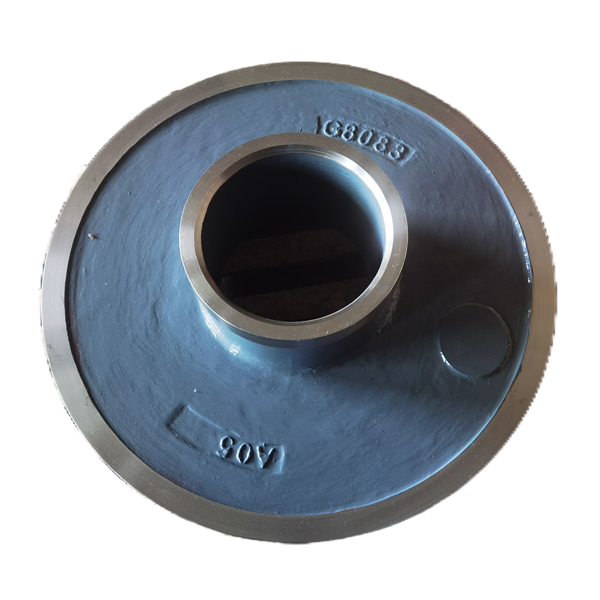

Product detail pictures:

Related Product Guide:

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Good Quality Sand And Gravel Pump - 8x6E-TG Gravel Pump, interchangeable with Warman pumps – Ruite Pump , The product will supply to all over the world, such as: Angola, USA, Poland, Although continuous opportunity, we have now now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.