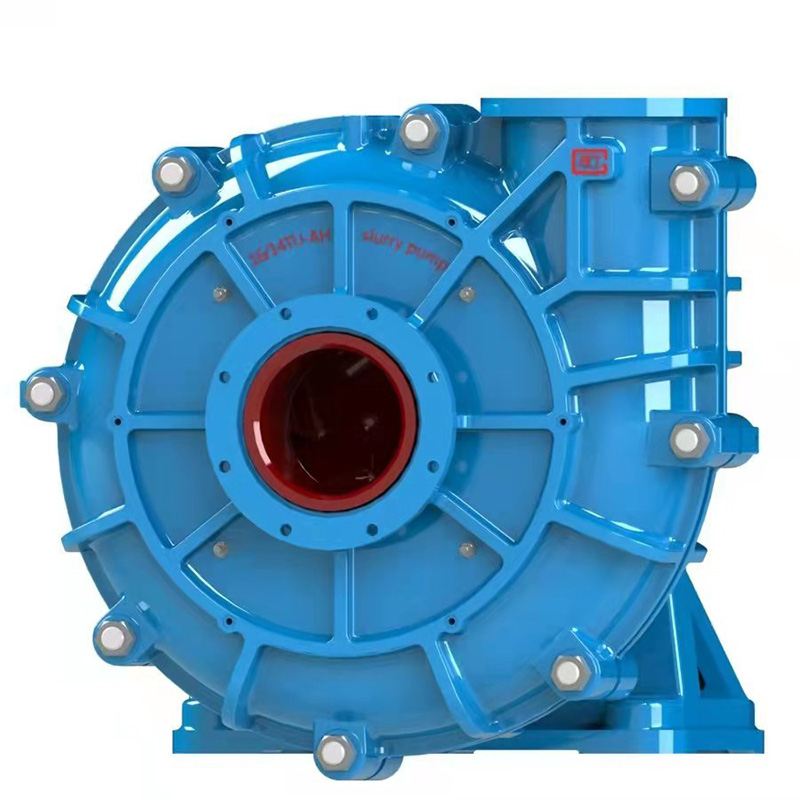

Good quality Dredge Booster Pump - High efficiency TZJ slurry pump for coal, Quality and price concessions – Ruite Pump

Good quality Dredge Booster Pump - High efficiency TZJ slurry pump for coal, Quality and price concessions – Ruite Pump Detail:

Feature

- horizontal centrifugal pump

- Abrasion resistant wet parts

- easy to maintain

- Packing or mechanical seal

- Protective shell surrounding the casing ideal for heavy duty

- Hydraulic optimization design, high-efficient, energy-saving and stable operation

- CAM design is based on the theories of modern hydromechanics and mechanics

- The wet parts adopt interchangeable anti-abrasive and anti-corrosive alloy material

- The metric bearing is lubricated by oil; scientific lubricating and cooling system ensure that the bearing operates under low temperature

- Complete range of pump models can meet various requirements and site working conditions

Applications

- Coal washery, coal preparation plant

- Metallurgy dressing works

- Alumina refinery, alumina plant

- Ball mill recirculation pump

- Hydro cyclone feed pump

- Power plant ash handling system

- Special abrasion condition

Product detail pictures:

Related Product Guide:

Just about every member from our large efficiency income crew values customers' wants and enterprise communication for Good quality Dredge Booster Pump - High efficiency TZJ slurry pump for coal, Quality and price concessions – Ruite Pump , The product will supply to all over the world, such as: Milan, Jersey, Kyrgyzstan, Our company will continue to adhere to the " superior quality, reputable, the user first " principle wholeheartedly. We warmly welcome friends from all walks of life to visit and give guidance, work together and create a brilliant future!

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.