-

China Cheap price Pond Dredge Pump - Rubber Cover Pate Liner – Ruite Pump

Slurry Pump Rubber Cover Plate Liner is the main wear parts for the rubber lined slurry pump. It forms a pump chamber with frame plate liner and throat bush to contact with slurries, As one of main wetted parts, Cover plate liner is very easily worn-out components because it works under longtime impact of abrasive and corrosive slurries in the high speed conditions, So the materials is very crucial to lifetime of complete pump, Ruite provides a complete rubber and metal materials selection fo... -

High Quality Ah Slurry Pump - Rubber Cover Pate Liner – Ruite Pump

Slurry Pump Rubber Cover Plate Liner is the main wear parts for the rubber lined slurry pump. It forms a pump chamber with frame plate liner and throat bush to contact with slurries, As one of main wetted parts, Cover plate liner is very easily worn-out components because it works under longtime impact of abrasive and corrosive slurries in the high speed conditions, So the materials is very crucial to lifetime of complete pump, Ruite provides a complete rubber and metal materials selection fo... -

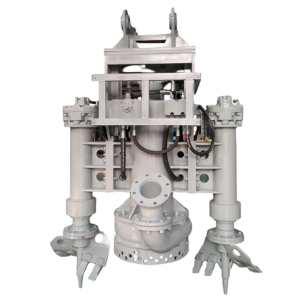

China wholesale 2 Inch Dredge Pump - THQ Hydraulic Submersible Slurry Pump – Ruite Pump

THQ Hydraulic Submersible Slurry Pump is designed for handling rocks, slurry, gravel, sand, stone, minerals, bentonite and others, with the shortest delivery times. Hydroman pumps deliver massive solids production at very low operational costs. The THQ hydraulic slurry pump can install cutters or agitators on various excavators to work like submersible dredging pumps, It can be also used in various hydraulic stations. Design Features: √ Submersible heavy duty agitator pump, hydraulic driven w... -

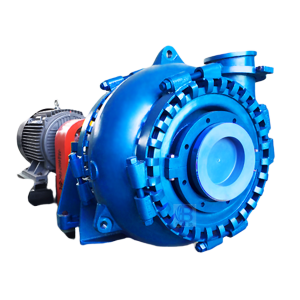

China Gold Supplier for Trash Slurry Pump - TGH High Head Gravel Pump, Highly efficient and stable – Ruite Pump

TGH High Head Gravel Pumps are Capable of handling large particles at consistently high head, high pressure, long distance, resulting in lower costs. Casing is designed with a large volume internal profile to reduce associated velocities which prolong component life. Designed to pump extremely aggressive gravels with a wide particle distribution. The GH gravel pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. A wide v... -

Factory directly Diesel Sand Pump - WN Dredge pump river dredging – Ruite Pump

Description WN series dredge pump is a kind of new type dredging pump developed by our company using various advanced computer aided design software, aiming at the current situation of dilapidated, dredging and reclamation of rivers and lakes. This serie of dredge pumps has features as follows:excellent performance, long life, high efficiency, reliable shaft seal, considerable economic benefits, and so on.Which allows it to completely meet the needs of customers, also pass the CCS ... -

Best Price for Slurry Transport Using Centrifugal Pumps - Rubber Frame Plate Liner – Ruite Pump

Slurry Pump Rubber Frame Plate Liner is the main wear parts for the rubber lined slurry pump. It forms a pump chamber with cover plate liner and throat bush to contact with slurries, As one of main wetted parts, Frame plate liner very easily worn-out components because it works under longtime impact of abrasive and corrosive slurries in the high speed conditions, So the materials is very crucial to lifetime of complete pump, Ruite provides a complete rubber materials selection for most all du... -

Good Quality Slurry Pump Components - TGQ Submersible Gravel Pump – Ruite Pump

Durable, electro-submersible Gravel pump. Versatile and rugged solution for the transfer of abrasive and high density slurries on mining, civil construction, inrustry and otherheavy duty applications. The pump casing features a large clearance which allows the easy passage of large solids and reduces wear and erosion to improve service life and prevent loss of efficiency. TGQ series heavy duty submersible Gravel pump is designed and suitable for conveying liquid with slurry, big solid particl... -

Factory Cheap Submersible Dredge Pump - 300TV-TSP Vertical Slurry Pump – Ruite Pump

300TV-TSP Vertical Slurry Pump is designed to be immersed in liquid for conveying abrasive, coarse particles, dirty water and particle contaminated water. Due to the design of the pump assembly, a shaft seal is not required and the pump can be operated in conditions that most pumps would have a low service life and their seal arrangement would not be effective. Design Features • Fully Cantilevered – Eliminates submerged bearings, packing, lip seals, and mechanical seals that other verti... -

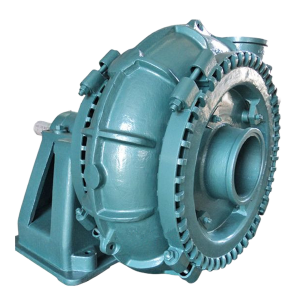

China Supplier Ceramic Slurry Pump - TG Gravel Sand Pump Treatment of large particle slurry – Ruite Pump

TG/TGH Sand Gravel Pumps are designed specifically for continuous pumping of extremely aggressive slurries, gavels, and sands. with a wide particle size distribution. Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life. Design Features √ The unique segmented clamp ring on larger size units and solid on smaller pumps, facilitates ca... -

China Gold Supplier for Trash Slurry Pump - AHF Horizontal Froth Pumps, Chinese manufacturers – Ruite Pump

AHF Horizontal Froth Pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth. Design Features: •Based on the AH or L series slurry pumps •Existing AH or L series slurry pumps can be converted to AHF/MF/LF horizontal froth pumps with only a few modifications •Inducer blade impeller for positive froth feed •Enlarged high efficiency slurry throatbush to maximize the inlet size and reduce NPSH required •Standard AH or L slurry pump mounting and flange center lines •Avai... -

Chinese wholesale 4 Inch Dredge Pump - 12/10 ST-THR rubber lined slurry pumps, designed for handling highly abrasive – Ruite Pump

12/10ST-THR Rubber Lined Slurry Pump is cantilevered, horizontal, centrifugal slurry pumps for handling of highly abrasive, high-density slurries and support multistage serial installation. They feature frame and cover plates made out of grey cast iron or ductile cast iron (based on the pressure requirements) with replaceable wear-resistant rubber liners, rubber impellers, 8 position discharge branch and gland or expeller type shaft seals. Additionally they are available with several drive ty... -

Best quality Underwater Dredger Pump - Rubber Lined Slurry Pump Parts – Ruite Pump

Rubber Lined Slurry Pump Parts namely the rubber parts have direct connection with slurries, They are very easily worn-out components because they work under longtime impact of abrasive and corrosive slurries in the high speed, The wetted parts include impeller, cover plate liner, frame plate liner, throatbush, frame plate liner insert etc, These wear parts are very crucial to the service life of slurry pumps, For the long service life of pump parts, the material plays an important role here,...