-

Factory source Slurry Pumps And Engineers - WN Dredge pump river dredging – Ruite Pump

Description WN series dredge pump is a kind of new type dredging pump developed by our company using various advanced computer aided design software, aiming at the current situation of dilapidated, dredging and reclamation of rivers and lakes. This serie of dredge pumps has features as follows:excellent performance, long life, high efficiency, reliable shaft seal, considerable economic benefits, and so on.Which allows it to completely meet the needs of customers, also pass the CCS ... -

Hot-selling Submerged Slurry Pump - AHF froth pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth – Ruite Pump

A large oversized inlet with a unique impeller inducer blade can easily handle heavy froth and higher viscosity dense slurry. The semi-open metal impeller with screw compression function has a high head and is suitable for conveying high air content pulp. Higher efficiency and lower energy consumption. Features / Benefits 1.Size range (discharge) :2″ to 22″ (50 mm to 550 mm) 2.Capacities to:20,000 gpm (3,150 m3/hr) 3.Heads to: 120 ft (37 m) 4.Pressures to: 500 psi (3,445... -

Factory made hot-sale Gravel Cleaning Pump - Rubber Cover Pate Liner – Ruite Pump

Slurry Pump Rubber Cover Plate Liner is the main wear parts for the rubber lined slurry pump. It forms a pump chamber with frame plate liner and throat bush to contact with slurries, As one of main wetted parts, Cover plate liner is very easily worn-out components because it works under longtime impact of abrasive and corrosive slurries in the high speed conditions, So the materials is very crucial to lifetime of complete pump, Ruite provides a complete rubber and metal materials selection fo... -

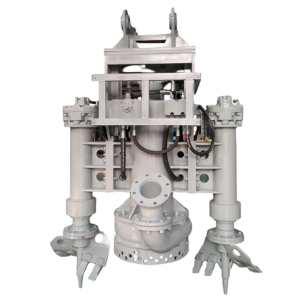

New Arrival China High Pressure Dredge Pump - THQ Hydraulic Submersible Slurry Pump – Ruite Pump

THQ Hydraulic Submersible Slurry Pump is designed for handling rocks, slurry, gravel, sand, stone, minerals, bentonite and others, with the shortest delivery times. Hydroman pumps deliver massive solids production at very low operational costs. The THQ hydraulic slurry pump can install cutters or agitators on various excavators to work like submersible dredging pumps, It can be also used in various hydraulic stations. Design Features: √ Submersible heavy duty agitator pump, hydraulic driven w... -

OEM Supply Rubber Lined Slurry Pumps - TGQ Submersible Gravel Pump – Ruite Pump

Durable, electro-submersible Gravel pump. Versatile and rugged solution for the transfer of abrasive and high density slurries on mining, civil construction, inrustry and otherheavy duty applications. The pump casing features a large clearance which allows the easy passage of large solids and reduces wear and erosion to improve service life and prevent loss of efficiency. TGQ series heavy duty submersible Gravel pump is designed and suitable for conveying liquid with slurry, big solid particl... -

High reputation Ground Type Slurry Pump - Rubber Cover Pate Liner – Ruite Pump

Slurry Pump Rubber Cover Plate Liner is the main wear parts for the rubber lined slurry pump. It forms a pump chamber with frame plate liner and throat bush to contact with slurries, As one of main wetted parts, Cover plate liner is very easily worn-out components because it works under longtime impact of abrasive and corrosive slurries in the high speed conditions, So the materials is very crucial to lifetime of complete pump, Ruite provides a complete rubber and metal materials selection fo... -

OEM manufacturer Engine Driven Slurry Pumps - Slurry Pump Expeller Ring – Ruite Pump

Slurry Pump Expeller Ring is used for AH/HH/L/M slurry pumps, The expeller ring is together work with expeller for the slurry pumps. They can not only help seal the pump, but also reduce the centrifugal force. The design and material of expeller is significant to its service life, Tobee offers expeller in cast iron, high chrome and rubber materials for options. Slurry Pump Expeller Ring Code: Slurry Pump Expeller Ring AH Slurry Pumps Slurry Pump Materials B029 1.5/1B-AH, 2/1.5B-... -

Renewable Design for Slurry Booster Pump - 1.5/1B-TH small Slurry Pump Supplier – Ruite Pump

Description TH series are single-stage, single-suction, cantilever, double-shell, horizontal centrifugal slurry pumps.They are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries for Conveying strong corrosive, high-concentrative slurries.Especially suitable for a variety of harsh working conditions, it is the first choice for the transportation of mine mill slurry and tailings slurry.They are mainly used f... -

OEM China Lime Slurry Pump - AHF froth pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth – Ruite Pump

A large oversized inlet with a unique impeller inducer blade can easily handle heavy froth and higher viscosity dense slurry. The semi-open metal impeller with screw compression function has a high head and is suitable for conveying high air content pulp. Higher efficiency and lower energy consumption. Features / Benefits 1.Size range (discharge) :2″ to 22″ (50 mm to 550 mm) 2.Capacities to:20,000 gpm (3,150 m3/hr) 3.Heads to: 120 ft (37 m) 4.Pressures to: 500 psi (3,445... -

Factory made hot-sale Gravel Cleaning Pump - WN Dredge pump river dredging – Ruite Pump

Description WN series dredge pump is a kind of new type dredging pump developed by our company using various advanced computer aided design software, aiming at the current situation of dilapidated, dredging and reclamation of rivers and lakes. This serie of dredge pumps has features as follows:excellent performance, long life, high efficiency, reliable shaft seal, considerable economic benefits, and so on.Which allows it to completely meet the needs of customers, also pass the CCS ... -

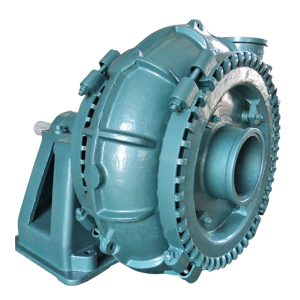

OEM Customized Electric Slurry Pump - 14x12T-TG Gravel Pump, Various drive types, interchangeable with Warman pumps – Ruite Pump

14x12T-TG Gravel pump is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Its wear parts made from high chrome alloy, The hardness can upto HRC65, Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life. Design Features • Bearing assembly — Large diameter shaf... -

High Quality Ah Slurry Pump - AF series froth pump for floatation process – Ruite Pump

The AF series froth pump is a product developed by Ruite. Based on the experience research and the actual needs of customers we developed this AF series. It is warmly welcomed by China’s market and has brought good customer benefits. During operation, the foam and foam in the slurry can be effectively eliminated, and it can operate normally even when the feed slurry is insufficient, so it is an ideal choice for conveying foamed slurry, especially in the flotation process. Overall perfor...