-

OEM/ODM China High Head Slurry Pump - WN Dredge pump river dredging – Ruite Pump

Description WN series dredge pump is a kind of new type dredging pump developed by our company using various advanced computer aided design software, aiming at the current situation of dilapidated, dredging and reclamation of rivers and lakes. This serie of dredge pumps has features as follows:excellent performance, long life, high efficiency, reliable shaft seal, considerable economic benefits, and so on.Which allows it to completely meet the needs of customers, also pass the CCS ... -

China Manufacturer for Thick Slurry Pump - WN Dredge pump river dredging – Ruite Pump

Description WN series dredge pump is a kind of new type dredging pump developed by our company using various advanced computer aided design software, aiming at the current situation of dilapidated, dredging and reclamation of rivers and lakes. This serie of dredge pumps has features as follows:excellent performance, long life, high efficiency, reliable shaft seal, considerable economic benefits, and so on.Which allows it to completely meet the needs of customers, also pass the CCS ... -

China Cheap price Slurry Pump For Sale - 10x8S-TG Gravel Pump, wide application, Highly efficient and stable – Ruite Pump

10x8S-TG Gravel Pumps are the most comprehensive range of centrifugal gravel sand pumps for use in mining, chemical and general industry applications. The horizontal sand gravel pumps are designed for heavy duty applications such as mining, power sector,dredging river,and tailings as well as specialty applications, which are used for continuous pumping of high abrasive, high density sand and gravels. 10x8S-TG Gravel Pump Wear Parts Design Impeller: Front and back shroud expulsion vanes reduce... -

China wholesale Sump Slurry Pump - Rubber Cover Pate Liner – Ruite Pump

Slurry Pump Rubber Cover Plate Liner is the main wear parts for the rubber lined slurry pump. It forms a pump chamber with frame plate liner and throat bush to contact with slurries, As one of main wetted parts, Cover plate liner is very easily worn-out components because it works under longtime impact of abrasive and corrosive slurries in the high speed conditions, So the materials is very crucial to lifetime of complete pump, Ruite provides a complete rubber and metal materials selection fo... -

OEM/ODM Factory Portable Slurry Pump - 200SV-TSP Vertical Slurry Pump – Ruite Pump

200SV-TSP Vertical Slurry Pump is designed for applications requiring greater reliability and durability than conventional vertical process pumps can offer. Fully elastomer lined or hard metal fitted. No submerged bearings or packing. High capacity double suction design. Optional recessed impeller and suction agitator available. Design Features Less wear, less corrosion Wetted components are available in a wide range of alloys and elastomers. Tobee selects the optimum combination of materials... -

Factory Free sample Mining Slurry Pump - WN Dredge pump river dredging – Ruite Pump

Description WN series dredge pump is a kind of new type dredging pump developed by our company using various advanced computer aided design software, aiming at the current situation of dilapidated, dredging and reclamation of rivers and lakes. This serie of dredge pumps has features as follows:excellent performance, long life, high efficiency, reliable shaft seal, considerable economic benefits, and so on.Which allows it to completely meet the needs of customers, also pass the CCS ... -

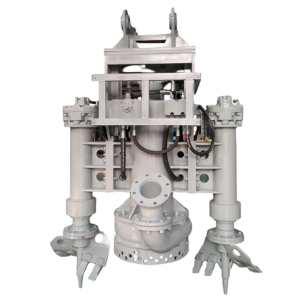

New Fashion Design for Slurry Agitator Pump - THQ Hydraulic Submersible Slurry Pump – Ruite Pump

THQ Hydraulic Submersible Slurry Pump is designed for handling rocks, slurry, gravel, sand, stone, minerals, bentonite and others, with the shortest delivery times. Hydroman pumps deliver massive solids production at very low operational costs. The THQ hydraulic slurry pump can install cutters or agitators on various excavators to work like submersible dredging pumps, It can be also used in various hydraulic stations. Design Features: √ Submersible heavy duty agitator pump, hydraulic driven w... -

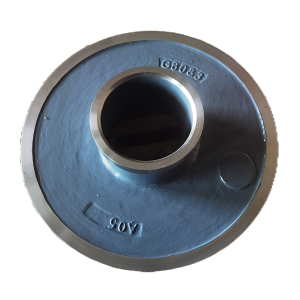

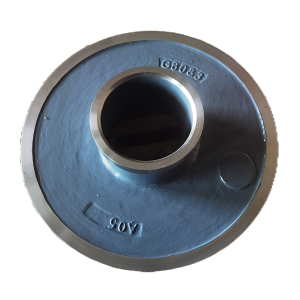

Fixed Competitive Price Slurry Mixer Pump - Slurry Pump Throatbush – Ruite Pump

Throatbush is one of wet parts of slurry pumps. It links plate liner and forms a Pump chamber to work with impeller. As a wet part, its material is very important and Ruite pump offer high chrome white iron (%27chrome) throatbush which is very abrasive-resistant. Slurry Pump Throat Bush is interchangeable with AH/HH/L/M slurry pump throat bush, It links plate liner and forms a Pump chamber to work with impeller, as one of wetted parts for the slurry pump, Its wear-resistance is very important... -

Good Quality Horizontal Froth Slurry Pump - AHF Horizontal Froth Pumps, Chinese manufacturers – Ruite Pump

AHF Horizontal Froth Pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth. Design Features: •Based on the AH or L series slurry pumps •Existing AH or L series slurry pumps can be converted to AHF/MF/LF horizontal froth pumps with only a few modifications •Inducer blade impeller for positive froth feed •Enlarged high efficiency slurry throatbush to maximize the inlet size and reduce NPSH required •Standard AH or L slurry pump mounting and flange center lines •Avai... -

High Quality for Ash Slurry Pumps - China 6/4 D-TH Slurry Pump and Spare Parts – Ruite Pump

Description TH series are single-stage, single-suction, cantilever, double-shell, horizontal centrifugal slurry pumps.They are widely used in mining, metallurgy, coal washing, power plant, sewage water treatment, dredging, and chemical and petroleum industries for Conveying strong corrosive, high-concentrative slurries.Especially suitable for a variety of harsh working conditions, it is the first choice for the transportation of mine mill slurry and tailings slurry.They are mainly used f... -

Slurry Pump Throatbush – Ruite Pump

Throatbush is one of wet parts of slurry pumps. It links plate liner and forms a Pump chamber to work with impeller. As a wet part, its material is very important and Ruite pump offer high chrome white iron (%27chrome) throatbush which is very abrasive-resistant. Slurry Pump Throat Bush is interchangeable with AH/HH/L/M slurry pump throat bush, It links plate liner and forms a Pump chamber to work with impeller, as one of wetted parts for the slurry pump, Its wear-resistance is very important... -

2022 wholesale price Warman Slurry Pump - Slurry Pump Expeller – Ruite Pump

Slurry Pump Expeller is a very important slurry pump part if the expeller seal is selected for the slurry pump. It can not only help seal the slurry pump, but also reduce the centrifugal force. The design and material of expeller is significant to its service life because it is also one of the wet parts, Ruite offers expeller in cast iron and high chrome materials for options. Slurry Pump Expeller Code Slurry Pump Expeller Code AH Slurry Pump Slurry Pump Materials B028 1.5/1B-AH...