Factory Supply 1000m3/H Diesel Dredging River Dewatering Pump

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Factory Supply 1000m3/H Diesel Dredging River Dewatering Pump, We warmly welcome shoppers from everywhere in the world for almost any form of cooperation with us to make a mutual benefit long term. We’re devoting ourselves wholeheartedly to offer buyers the ideal service.

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for China Dewatering Pumps Mining and Electric Power Dewatering Pump, Customer satisfaction is our goal. We’re looking forward to cooperating with you and providing our best services in your case. We warmly welcome you to contact us and remember to feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

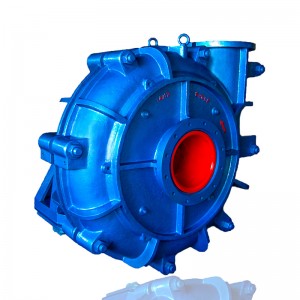

12x10G-TG Gravel pump is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life. 12×10 Sand Gravel Pumps are used to delivery slurry in mining, explosive sludge in metal melting, grudging in dredger and course of river and other fields.

Design Features:

• Advanced hydraulic model, CAD 3D design, high efficiency and obvious energy-saving

• Large dredging sand depth, high density of dredging mud, good pump NPSH and strong suction lift ability.

• Strong through-put, The dredging pump can persistently discharge gravel, high plastic soil lump,etc.

• Wide application, The sand pump can be used in various kinds of soil quality.

• The G sand pump can be directly matched with electric motor or diesel engine.

• The G sand pump impeller is 3 or 5 vanes for large particles delivering.

• Little hydraulic loss, high efficiency and low oil-consumption.

• Steady operating, little vibration, low noise.

• Simple & reliable construction, easily disassembly & assembly, convenient maintain.

• Reliable sealing without leakage.

• Long operating life of wear parts.

12/10G-TG Gravel Sand Pump Performance Parameter

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

12x10G-TG |

600 |

360-1440 |

10-60 |

400-850 |

65 |

1.5-4.5 |

667 |

12x10G-TG Dredging Sand Pump Shaft Seal Arrangement

• Packing Seal is a general shaft seal.It applies to various pumping conditions, PTFE and Graphite materials of Packing can be used in high corrosive slurries or high temperature conditions.Using ceramic shaft sleeve,For high abrasion conditions, The ceramic shaft sleeve is available.

• Expeller Seal is an impeller force of reversed centrifugal force, preventing slurry leakage. Expeller seal can be used on the single-stage pump when the positive pressure of pump inlet is no more than 10% of pump outlet pressure or on the first-stage pump in the pump series.

• Mechanical Seal is advanced sealing technique without sealing leakage, integrating construction, convenient installation & replacement, various constructions suit for all kinds of conditions.

12/10G-TG Gravel Pump Applications

• Mine: Black, non-ferrous ore slurry material pump and all kinds of concentrate and tailings conveying.

• Metallurgy: Transport various slurry for aluminium or steel manufacture.

• Coal: Coal mining, washing and various coarse and fine coal slurry transportation.

• Electricity: Remove power plant ash,wash ash,various ash dregs or ash slurry transportation.

• Construction materials: Various mud sand slurry(such as Cement slurry) transportation.

• Chemical: Phosphatic fertilizer or potassic fertilizer factory various abrasive slurry transportation.

• Water conservancy: Lake, river dredge, sediment, grit, High plastic clay suction line to transportation.

Note:

12×10 G-TG gravel pumps and spares are only interchangeable with Warman® 12×10 G-G gravel pumps and spares.

Our company since its inception, constantly regards product or service high quality as business life, continually improve creation technology, make improvements to product high-quality and consistently strengthen business total high-quality management, in strict accordance together with the national standard ISO 9001:2000 for Factory Supply 1000m3/H Diesel Dredging River Dewatering Pump, We warmly welcome shoppers from everywhere in the world for almost any form of cooperation with us to make a mutual benefit long term. We’re devoting ourselves wholeheartedly to offer buyers the ideal service.

Factory Supply China Dewatering Pumps Mining and Electric Power Dewatering Pump, Customer satisfaction is our goal. We’re looking forward to cooperating with you and providing our best services in your case. We warmly welcome you to contact us and remember to feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specifications or inquiries today.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |