Factory supplied Sand Pump For Sale - THQ Hydraulic Submersible Slurry Pump – Ruite Pump

Factory supplied Sand Pump For Sale - THQ Hydraulic Submersible Slurry Pump – Ruite Pump Detail:

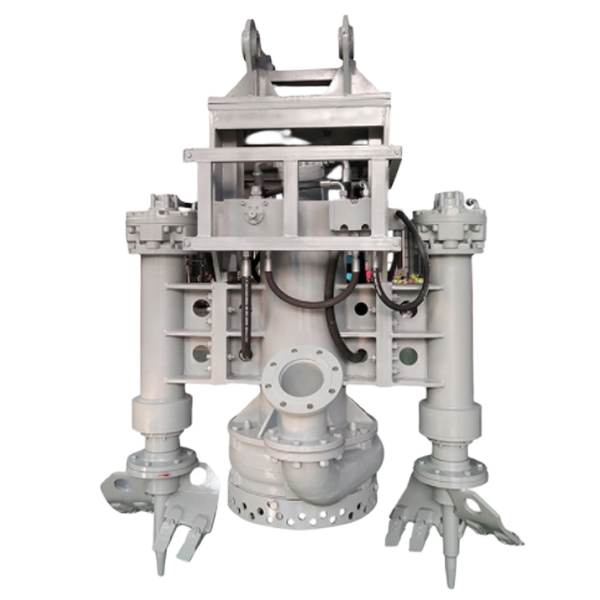

THQ Hydraulic Submersible Slurry Pump is designed for handling rocks, slurry, gravel, sand, stone, minerals, bentonite and others, with the shortest delivery times. Hydroman pumps deliver massive solids production at very low operational costs. The THQ hydraulic slurry pump can install cutters or agitators on various excavators to work like submersible dredging pumps, It can be also used in various hydraulic stations.

Design Features:

√ Submersible heavy duty agitator pump, hydraulic driven with variable RPM

√ All Pumps have standard high efficiency agitator to lift settled solids.

√ High abrasion resistance with high chrome wear parts.

√ Low rotation speed to reduce wear effect.

√ Agitators, Cutters, Excavators are available for options

√ Able to handle up to 70% solids by weight.

√ Easy installation on the boom of hydraulic excavators.

THQ Hydraulic Submersible Slurry Pumps Performance Parameters:

|

Model |

Discharge size |

Capacity |

Head |

Speed (rpm) |

Power |

Max. Particle (mm) |

Displacement (c.c.) |

Pressure (bar) |

Oil flow rate |

|

THQ24 |

100 |

60-80 |

18-28 |

1500-2000 |

10-19 |

25 |

20 |

210-300 |

30-40 |

|

THQ35A |

100 |

120-140 |

20-28 |

980-1180 |

18-25 |

35 |

55 |

210-250 |

54-65 |

|

THQ35B |

150 |

140-170 |

14-20 |

980-1180 |

18-25 |

35 |

55 |

210-250 |

54-65 |

|

THQ50A |

100 |

90-108 |

30-42 |

980-1180 |

25-37 |

35 |

75 |

210-250 |

74-89 |

|

THQ50B |

150 |

140-170 |

28-32 |

980-1180 |

25-37 |

35 |

75 |

210-250 |

74-89 |

|

THQ50HC |

150 |

210-250 |

15-21 |

980-1180 |

25-37 |

60 |

75 |

210-250 |

74-89 |

|

THQ85A |

150 |

200-240 |

22-30 |

980-1180 |

44-62 |

60 |

108 |

250-300 |

106-130 |

|

THQ85B |

200 |

350-420 |

16-23 |

980-1180 |

44-62 |

60 |

108 |

250-300 |

106-130 |

|

THQ85HC |

250 |

720-860 |

5-7 |

980-1180 |

44-62 |

90 |

108 |

250-300 |

106-130 |

|

THQ175A |

200 |

350-420 |

30-43 |

750-900 |

75-128 |

60 |

335 |

210-260 |

252-302 |

|

THQ220A |

250 |

720-780 |

22-26 |

600-650 |

110-160 |

120 |

500 |

230-300 |

300-325 |

|

THQ220B |

300 |

900-975 |

18-21 |

600-650 |

110-160 |

120 |

500 |

230-300 |

300-325 |

|

THQ300A |

250 |

720-900 |

22-34 |

600-750 |

110-214 |

120 |

500 |

230-350 |

300-375 |

|

THQ300B |

300 |

900-1200 |

18-28 |

600-750 |

110-214 |

120 |

500 |

230-350 |

300-375 |

|

THQ400A |

300 |

950-1000 |

34-42 |

750-850 |

239-295 |

120 |

710 |

270-300 |

535-605 |

|

THQ400B |

350 |

1100-1200 |

28-34 |

750-850 |

239-295 |

120 |

710 |

270-300 |

535-605 |

THQ Hydraulic Submersible Slurry Pumps Applications:

Industry: Pumping industrial waste, extraction of slag, forge scale, cal-cines, sludge, setting sludge, petroleum and tar residues, Thermal Power plants – Ash pits, Construction and public works, Inert wash sludge, Marble dust, All types of effluent with solids in suspension, Sewage, De-watering etc

Dredging, Sand & Gravel: Sand extraction and transport, Sand and gravel mining, Dredging harbors and marinas, Port maintenance, Dredging of canals and harbors, Clean-up of rivers, lakes and lagoons, Dam dredging, Beach reclamation, Heavy soils etc

Mining: Mining and tailings reclamation, Clean-up of setting tanks, Extraction of coal, minerals and sand etc.

Offshore: Underwater work, Ecological recovery, Clean-up of locks, Emptying of caissons and bulkheads, Barge transfer etc

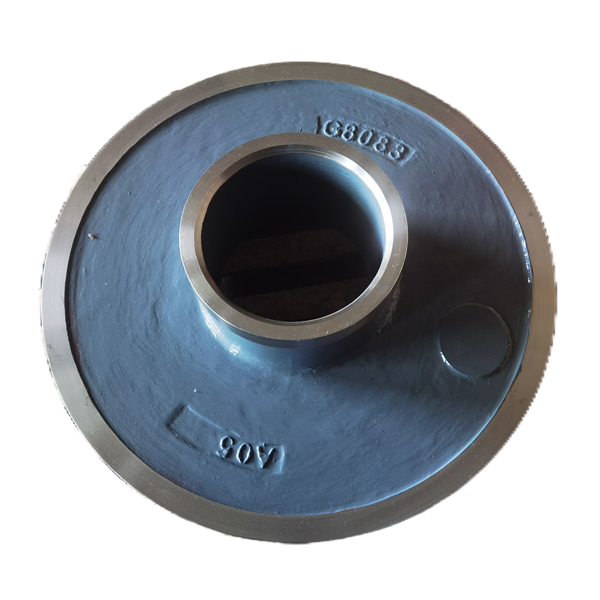

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Factory supplied Sand Pump For Sale - THQ Hydraulic Submersible Slurry Pump – Ruite Pump , The product will supply to all over the world, such as: Johannesburg, Amsterdam, Las Vegas, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.