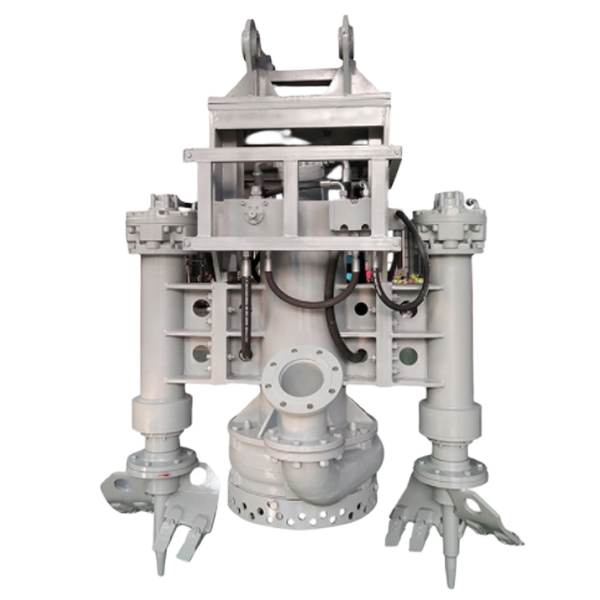

Factory Promotional Backwash Sand Pump - THF froth pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth – Ruite Pump

Factory Promotional Backwash Sand Pump - THF froth pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth – Ruite Pump Detail:

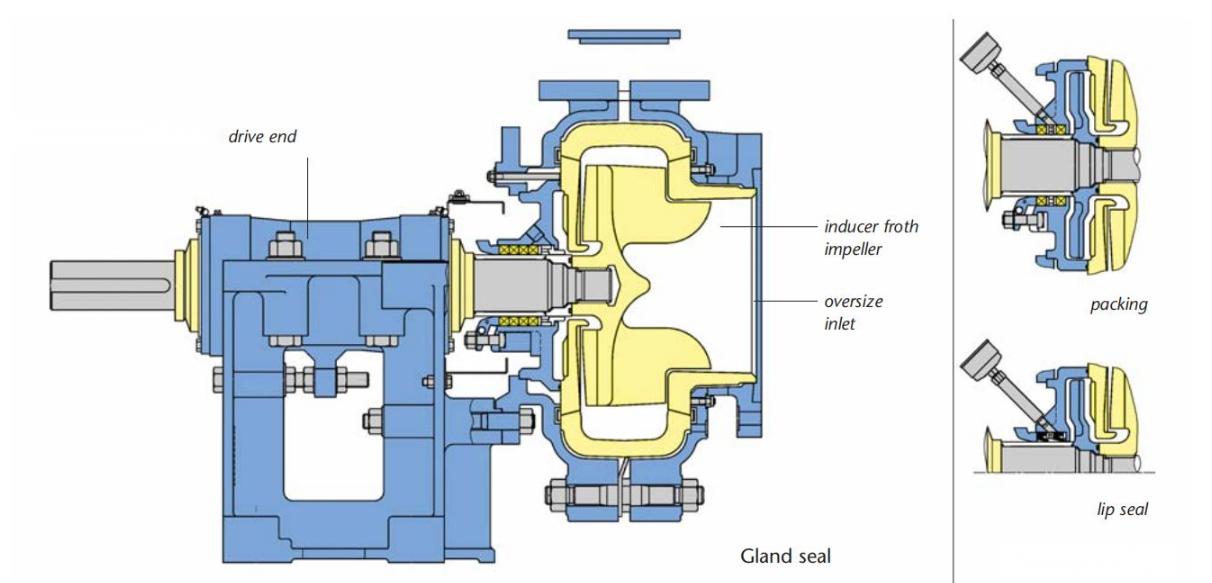

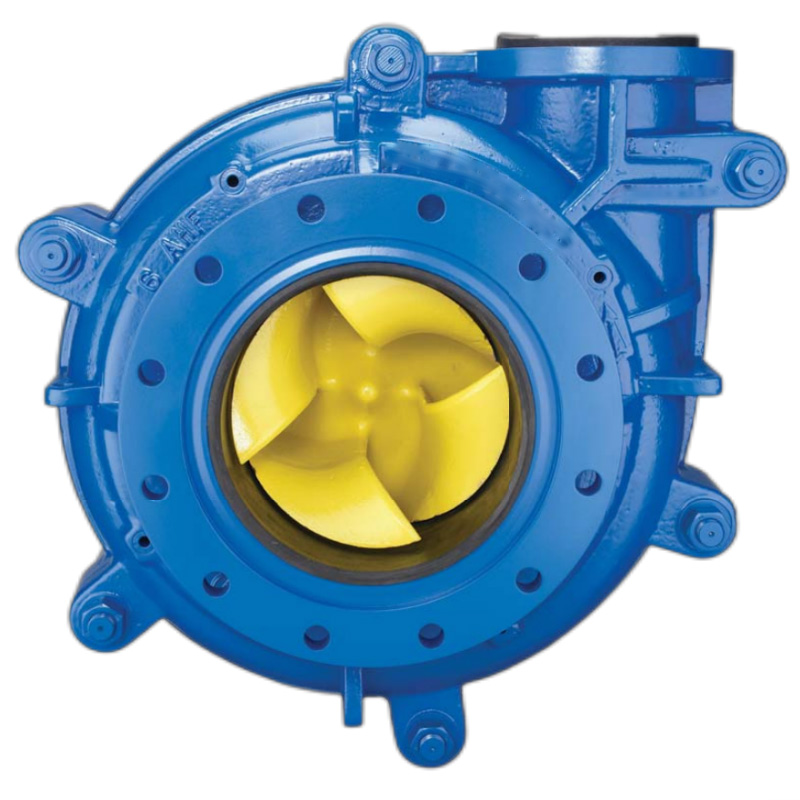

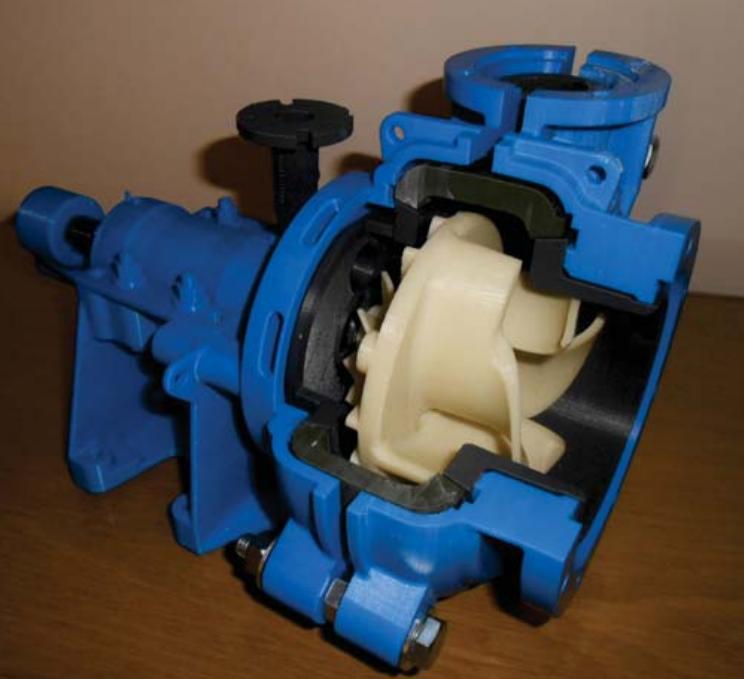

A large oversized inlet with a unique impeller inducer blade can easily handle heavy froth and higher viscosity dense slurry.

The semi-open metal impeller with screw compression function has a high head and is suitable for conveying high air content pulp.

Higher efficiency and lower energy consumption.

Features / Benefits

1.Size range (discharge) :2″ to 22″ (50 mm to 550 mm)

2.Capacities to:20,000 gpm (3,150 m3/hr)

3.Heads to: 120 ft (37 m)

4.Pressures to: 500 psi (3,445 kPa)

Product detail pictures:

Related Product Guide:

We stick to our enterprise spirit of "Quality, Performance, Innovation and Integrity". We purpose to create a lot more price for our prospects with our rich resources, innovative machinery, experienced workers and great products and services for Factory Promotional Backwash Sand Pump - THF froth pumps are heavy duty horizontal pumps designed to handle difficult tenacious froth – Ruite Pump , The product will supply to all over the world, such as: Marseille, Tajikistan, Mexico, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We have been able to also deliver you with cost-free samples to meet your specs. Ideal efforts will probably be produced to deliver you the most beneficial service and solutions. Should really you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We will constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. You should feel absolutely free to speak to us for organization. nd we believe we are going to share the best trading practical experience with all our merchants.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.