Factory Directly supply Centrifugal Sanb Mud Ash Gravel Mining Slurry Pump

We’re committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Factory Directly supply Centrifugal Sanb Mud Ash Gravel Mining Slurry Pump, Make sure you sense absolutely absolutely free to speak to us for organization. nd we believe we are going to share the ideal trading practical experience with all our merchants.

We’re committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for China Centrifugal Slurry Pump and Slurry Pump, Certainly, competitive price, suitable package and timely delivery might be assured as per customers’ demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

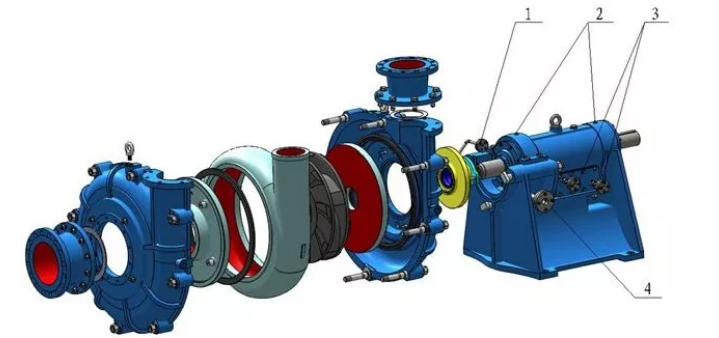

100 ZJ-36 SLURRY PUMP DETAILS

1. The wet parts for slurry pump are made of wear-resistant high chromium alloy or rubber, customized according to buyer’s requirements.

2. Slurry pump’s bearing assembly use cylindrical structure, adjusting the space between impeller and front liner easily. They can be removed completely when being repaired. Bearing assembly use grease lubrication.

3. The shaft seal could use the packing seal, expeller seal and mechanical seal.

4. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

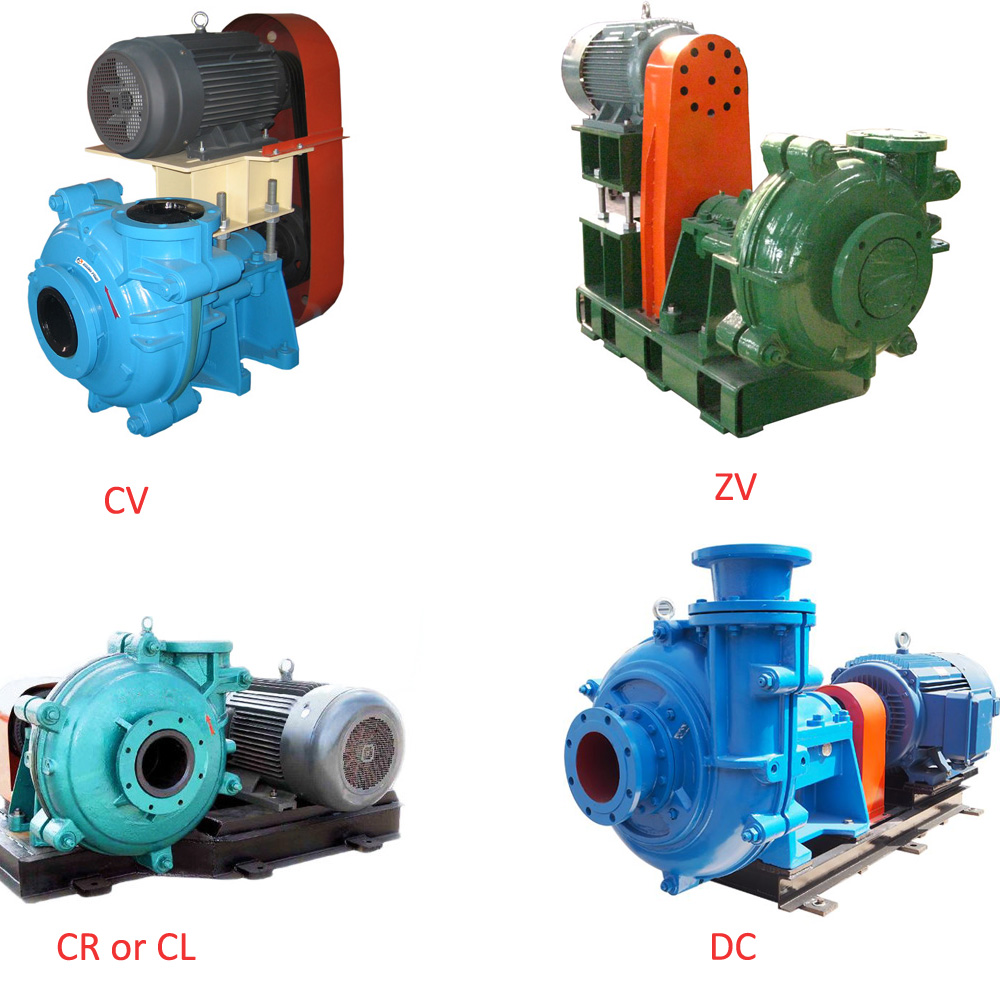

5. There are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices for the slurry pump.

6. Wide performance, good NPSH and high efficiency. The slurry pump can be installed in multistage series to meet the delivery for long distance.

ZJ Slurry Pump Technical Data

| Size | Capacity(m3/h) | Head(m) | Max.Power(KW) | Speed(r/min) | NPSHm |

| 40ZJ | 5.0-20 | 6.0-29 | 4 | 1390-2890 | 2.5 |

| 50ZJ | 12-39 | 2.6-10.2 | 4 | 940-1440 | |

| 65ZJ | 20-80 | 7.0-33.6 | 15 | 700-1480 | 3 |

| 80ZJ | 41-260 | 8.4-70.6 | 75 | 700-1480 | 3.5 |

| 100ZJ | 57-360 | 7.7-101.6 | 160 | 700-1480 | 4.1 |

| 150ZJ | 93-600 | 9.1-78.5 | 200 | 500-980 | 3.9 |

| 200ZJ | 215-900 | 215-900 | 355 | 500-980 | 4.4 |

| 250ZJ | 281-1504 | 13.1-110.5 | 800 | 500-980 | 5.3 |

| 300ZJ | 403-2166 | 10.0-78.0 | 630 | 400-590 | 4.8 |

100ZJ-36 slurry pump application

The pumps can be used in many applications, such as Pipeline transport, High velocity hydraulic transport, Mineral processing, Coal prep, Cyclone feeds, Aggregate processing, Fine primary mill grinding, Chemical slurry service, Tailings, secondary grinding, Industrial processing, Pulp and paper, Food processing, Cracking operations, Ash handling.

100ZJ-36 Slurry Pump Package and Shipping

The slurry pump or slurry pump parts will be packed in wooden case.

We will paste the shipping mark on the package according to buyer’s requirements.

For more information about our pumps, please send email to: rita@ruitepump.comWe’re committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Factory Directly supply Centrifugal Sanb Mud Ash Gravel Mining Slurry Pump, Make sure you sense absolutely absolutely free to speak to us for organization. nd we believe we are going to share the ideal trading practical experience with all our merchants.

Factory Directly supply China Centrifugal Slurry Pump and Slurry Pump, Certainly, competitive price, suitable package and timely delivery might be assured as per customers’ demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |