Factory best selling Slurry Pump Design - TGH High Head Gravel Pump, Highly efficient and stable – Ruite Pump

Factory best selling Slurry Pump Design - TGH High Head Gravel Pump, Highly efficient and stable – Ruite Pump Detail:

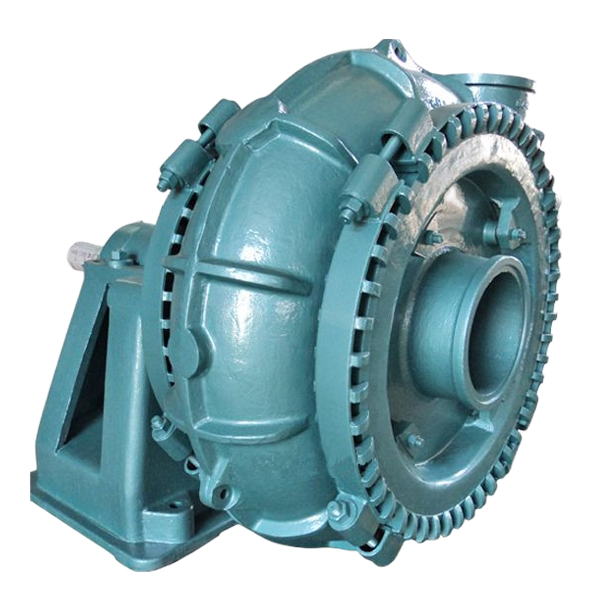

TGH High Head Gravel Pumps are Capable of handling large particles at consistently high head, high pressure, long distance, resulting in lower costs. Casing is designed with a large volume internal profile to reduce associated velocities which prolong component life. Designed to pump extremely aggressive gravels with a wide particle distribution. The GH gravel pump provides excellent wear life while maintaining efficiency during the wear cycle providing the best total operating cost. A wide variety of shaft seals provide a perfect fit for a wide range of applications.

Design Features

√ Modular design for ease of maintenance.

√ Large passage width designed to minimise internal velocities resulting in prolonged wear life.

√ Lifting points for easy maintenance.

√ Standard or advanced bearing assembly improves reliability to extend bearing life reduce lubrication costs.

√ Shaft sealing for increased reliability, stuffing box, expeller, elevated seal or mechanical seal options available.

√ Standard three vane large passage impellers to accommodate passing large particle sizes.

√ Single piece sleeve for stuffing box sealing, lowers stock holding and maintenance.

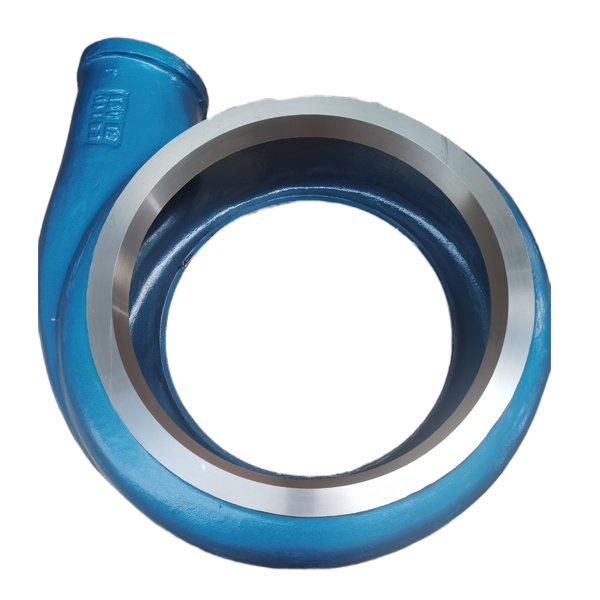

√ Segmented volute clamp ring allows casing rotation to any required position.

√ Casings fitted with inspection/flushing hole as optional extra.

√ Multi-purpose design allows for reduced inventory requirements and interchangeability.

√ Belt guards allows for ease of maintenance and inspection of belt condition.

TGH High Head Gravel Pumps Performance Parameters

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

10/8S-TGH |

560 |

180-1440 |

24-80 |

500-950 |

72 |

2.5-5 |

711 |

|

12/10G-TGH |

600 |

288-2808 |

16-80 |

350-700 |

73 |

2-10 |

950 |

|

16/14TU-TGH |

1200 |

324-3600 |

26-70 |

300-500 |

78 |

3-6 |

1270 |

|

18/16TU-TGH |

1200 |

720-5220 |

16-72 |

250-500 |

80 |

3-6 |

1067 |

TGH High Head Gravel Pump Typical Applications

Booster pumps, Large particles solids, Dredging, DMS circuits, Sugar beet, Sand reclamation, Suction hopper dredging, Slag granulation, Barge loading etc.

NOTE:

*TGH high head gravel pumps and spares are only interchangeable with Warman® GH high head gravel pumps and spares.

Product detail pictures:

Related Product Guide:

All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for Factory best selling Slurry Pump Design - TGH High Head Gravel Pump, Highly efficient and stable – Ruite Pump , The product will supply to all over the world, such as: Surabaya, Greek, Kuwait, We've got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.