Factory best selling Slurry Pump Design - Slurry Pump Parts – Ruite Pump

Factory best selling Slurry Pump Design - Slurry Pump Parts – Ruite Pump Detail:

Slurry Pump Parts are interchangeable with AH/HH/L/M slurry pump parts and designed by spatial structure CFD and impeller casting CAE,Precision casting and professional heat treatment process make the parts upto more higher hardness,Precision machining and painting technology ensure the parts are more conformable with fluidics,With strict quality control,Ruite’s high chrome wear parts provide users with longer 30%-60%wear life and higher efficiency due to advanced manufacturing processes.Increasing users enjoy perfect fit and finish to reduce installation workload.

Slurry Pumps Interchangeable parts

√Completely interchangeable with AH,AHR,HH,M,L horizontal slurry pumps,SP,SPR vertical slurry pumps,G,GH gravel sand pumps,AF froth slurry pumps etc

√Metal materials code:A03,A04,A05,A06,A07,A12,A14,A25,A33,A49,A51,A61

√Nature rubber materials code:R08,R24,R26,R33,R38,R55,R66

√Synthetic rubber materials code:S01,S10,S12,S21,S31,S42,S44,S50

√Polyurethane materials code:U01,U05

√Shaft material:45#,40CrMo,SS304,SS316

√Shaft sleeve material:SS410,SS420 SS304,SS316

√Lantern ring material:304,316,PTFE

√Bearing housing/bearing end cover material:G01,D21

√Expeller,Expeller ring:A05

√Packing:Q05

Standard Materials Description

Metal:

•KmTBCr27 is a wear resistant white cast iron that offers excellent performance under erosive conditions.The alloy can be effectively used in a wide range of slurry types.The high wear resistance of KmTBCr27 alloy is provided by the presence of hard carbides in the microstructure.KmTBCr27 Alloy is particularly suited to mild acidic duties where erosion resistance is required.

•KmTBCr28 is martensitic white iron with moderate erosion resistance.It has the main elements of Chrome 28%,low Carbon with hardness of 430 in Brinell,KmTBCr28 is a corrosion resistant white iron suitable for low PH corrosion duties,where erosive wear is also a problem.

•KmTBCr35 is a premium erosion/corrosion alloy,The main elements of Chrome is 35-45%,low Carbon with hardness of 450 in Brinell.KmTBCr35 Alloy is suitable for phosphoric acid duties,FGD duties,sulphuric acid,and other moderately corrosive applications.

Customized Materials:

Pump is always making continuous optimization of materials like Cast steel,EPDM,Hypalon,Hastelloy,CD4MCu,Viton,Fluoroplastic,Ceramic,Bronze,Titanium,Aluminum and other anti-abrasive&corrosive materials for various applications.

Slurry Pump Spare Parts Applications

Heavy Mining|Mineral Processing|Coal Prep|Cyclone Feeds|Aggregate Processing|Fine Primary Mill Grinding|Chemical Slurry Service|Tailings|Secondary Grinding|Industrial Processing|Pulp And Paper|Food Processing|Cracking Operations|Ash Handling|Pipeline Transport|High Velocity Hydraulic Transport|Food Processing|Explosive Sludge In Metal Smelting|River And Pond Dredging|Heavy Refuse Removal|Larger Particle Or Low NPSHA Applications|Continuous(Snore)Sump Pump Operation|Abrasive Slurries|High Density Slurries|Large Particle Slurries|Sump Drainage|Washdown|Floor Drainage|Mixing

Note:

*slurry pump spare parts are only interchangeable with Warman®slurry pump spare parts.

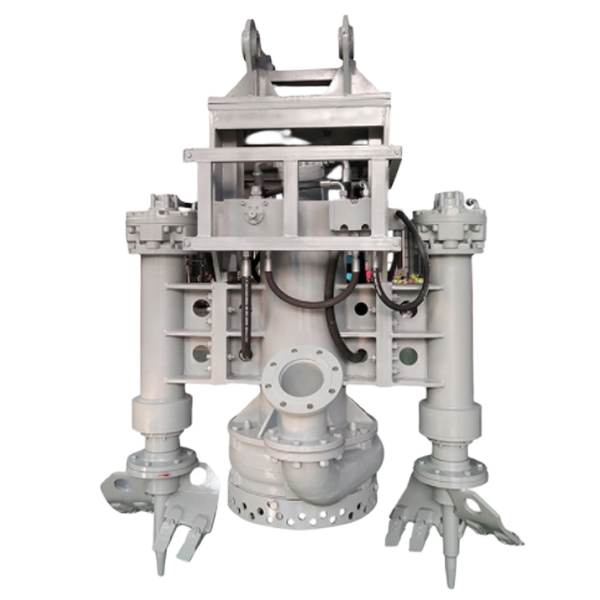

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand abroad business" is our progress strategy for Factory best selling Slurry Pump Design - Slurry Pump Parts – Ruite Pump , The product will supply to all over the world, such as: Turkey, Eindhoven, Turkey, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our products, just try to contact us for more details!

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!