Europe style for Slurry Pump Maintenance - ZJL Vertical Sump Pump – Ruite Pump

Europe style for Slurry Pump Maintenance - ZJL Vertical Sump Pump – Ruite Pump Detail:

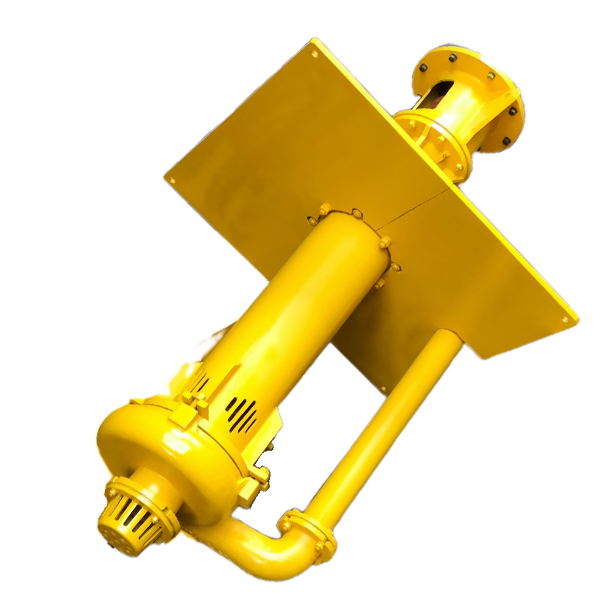

ZJL Vertical Sump Pump is vertical, axial-suction, single-state, single-suction, single casing and centrifugal structure. This series pumps through combine advantages of similar sump pumps from China & other countries, It has the features of high efficiency, energy conservation, wear resistance, small vibration, low noise, reliable operation and long service life. The comprehensive performance became the leading role of vertical sump pumps in China. ZJL vertical sump pumps are widely applied to transport slurries in mining, minerals processing, chemicals, Sewage, electric power, metallurgy, coal, building materials and other industries.

Design Features

√ Vertical, submerged, cantilever, sump pump design.

√ The pump wear parts made in anti-wear chrome alloy or anti-corrosive rubber.

√ High efficiency direct connection sump pump.

√ Light weight and long service life time.

√ Rational construction and reliable operation.

√ Lower noise and vibration.

√ No need of shaft seal water.

√ Submerged in sump for continuous operation.

√ Different submerged shaft length for options.

ZJL Vertical Sump Pumps Performance Parameters

|

Model |

Max. power P |

Clear water performance |

Max. Particle (mm) |

Weight |

|||

|

Capacity Q |

Head H |

Speed n |

Max. Eff. |

||||

|

150ZJL-B55B |

110 |

128.5-479.1 |

10.0-49.3 |

490-980 |

59.8 |

50 |

2112 |

|

150ZJL-A35 |

37 |

99-364 |

3.0-17.9 |

490-980 |

69.0 |

15 |

800 |

|

100ZJL-A34 |

45 |

74-293 |

5.5-36.8 |

700-1480 |

65.8 |

14 |

630 |

|

80ZJL-A36 |

45 |

50-201 |

7.3-45.5 |

700-1480 |

58.2 |

12 |

650 |

|

80ZJL-A36B |

45 |

51.1-220.5 |

6.4-44.9 |

700-1480 |

54.1 |

15 |

650 |

|

65ZJL-A30 |

18.5 |

18-98 |

5.9-34.7 |

700-1470 |

53.7 |

8 |

440 |

|

65ZJL-A30B |

22 |

27.9-105.8 |

7.1-34.4 |

700-1470 |

60.9 |

10 |

440 |

|

65ZJL-B30J |

15 |

18.9-84.2 |

5.8-32.3 |

700-1470 |

49.1 |

8 |

440 |

|

50ZJL-A45B |

55 |

22.9-107.4 |

11.4-74.0 |

700-1470 |

39.1 |

25 |

1106 |

|

50ZJL-B40 |

30 |

15-65 |

8.6-58.3 |

700-1470 |

34.1 |

9 |

540 |

|

50ZJL-A35 |

22 |

19-86 |

7.3-47.1 |

700-1470 |

48.1 |

15 |

500 |

|

50ZJL-A35B |

22 |

17.1-73 |

8.0-46.5 |

700-1470 |

45.1 |

20 |

500 |

|

50ZJL-A20 |

4 |

8-38 |

1.4-10.7 |

700-1470 |

38.6 |

10 |

240 |

|

50ZJL-A20J |

30 |

18-70 |

5.6-46.2 |

1440-2950 |

33.8 |

22 |

570 |

|

40ZJL-A35 |

18.5 |

9.4-47.6 |

8.1-48.0 |

700-1470 |

38.7 |

7 |

500 |

|

40ZJL-B25 |

4 |

4.9-22.9 |

4.0-21.5 |

700-1440 |

37.6 |

8 |

225 |

|

40ZJL-B25B |

5.5 |

4.9-24.2 |

3.5-19.1 |

700-1440 |

30.4 |

8 |

225 |

|

40ZJL-A21 |

4 |

4.6-25.9 |

3.3-17.0 |

700-1440 |

44.6 |

10 |

210 |

|

40ZJL-A21B |

4 |

5.8-25.2 |

2.5-14.6 |

700-1440 |

36.6 |

10 |

210 |

ZJL Vertical Sump Pumps Applications

The rugged ZJL Vertical Sump Pumps are available in a wide range of popular sizes to suit most pumping applications. Thousands of these pumps are proving their reliability and efficiency worldwide in:

• Minerals processing

• Coal preparation

• Chemical processing

• Effluent handling

• Sand and gravel

and almost every other tank, pit or hole-in-the ground slurry handling situation. The ZJL(R) design with either hard metal (ZJL) or elastomer covered (ZJLR) components makes it ideal for:

• Abrasive and/or corrosive slurries

• Large particle sizes

• High density slurries

• Continuous or “snore” operation

• Heavy duties demanding cantilever shafts

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Europe style for Slurry Pump Maintenance - ZJL Vertical Sump Pump – Ruite Pump , The product will supply to all over the world, such as: Rwanda, United States, Mexico, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.