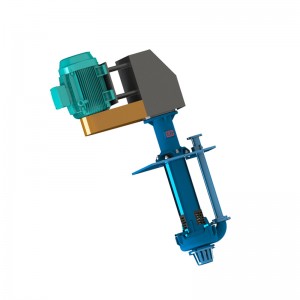

Europe style for High Quality Mining Machinery Laboratory Vertical Sand Pump for Conveying

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Europe style for High Quality Mining Machinery Laboratory Vertical Sand Pump for Conveying, Since establishment during the early 1990s, we have now create our sale network in USA, Germany, Asia, and several Middle Eastern countries. We aim to be a top class supplier for globally OEM and aftermarket!

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for China Lab Sand Pump and Mining Machinery Sand Pump, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our merchandise are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead’, we sincerely welcome clients from at home and abroad to cooperate with us.

Description

TSP Series vertical slurry pumps are no submerged bearings or seals cantilevered pumps, which ideal for a variety of submerged suction pumping applications. These pumps operate well in a variety of sump conditions, and can also be readily applied on floating dewatering or other floating pump platforms.

Wetted Parts

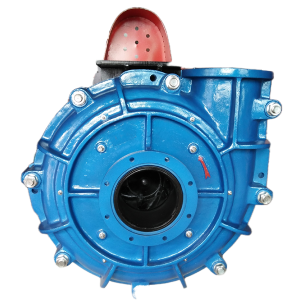

Liners – Hard metal liners are completely interchangeable with pressure molded elastomer. Elastomer seal rings back all liner joints. Easily replaceable liners are bolted, not glued, to the casing for positive attachment and east of maintenance.

Impeller – Hard metal and molded elastomer impellers are completely interchangeable. Front and rear shrouds have pump out vanes that reduce recirculation and seal contamination.

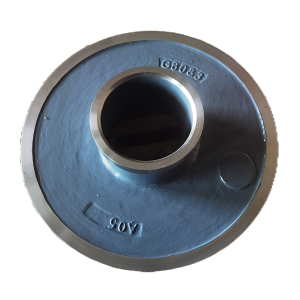

Throat bush – Hard metal and molded elastomer impellers are completely interchangeable. Wear is reduced and maintenance simplified by the use of tapered mating faces to allow positive accurate alignment during assembly and simple removal.

Feature

1.Single casing structure with the advantages of light weight, small volume, easy installation;

2.Anti-abrasive wet parts made of high-chrome alloys;

3.Transmission shaft and suction pipe could be chosen according to liquid surface of the slurry pool;

4.Slurry pump agitator could be installed to improve transfer efficiency;

5.Able to run smoothly under various speeds.

Parameter

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Europe style for High Quality Mining Machinery Laboratory Vertical Sand Pump for Conveying, Since establishment during the early 1990s, we have now create our sale network in USA, Germany, Asia, and several Middle Eastern countries. We aim to be a top class supplier for globally OEM and aftermarket!

Europe style for China Lab Sand Pump and Mining Machinery Sand Pump, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our merchandise are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ??customer first, forge ahead’, we sincerely welcome clients from at home and abroad to cooperate with us.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |