Cheapest Factory Dredge Pump - 1.5/1B-THR Rubber Slurry Pump high quality service – Ruite Pump

Cheapest Factory Dredge Pump - 1.5/1B-THR Rubber Slurry Pump high quality service – Ruite Pump Detail:

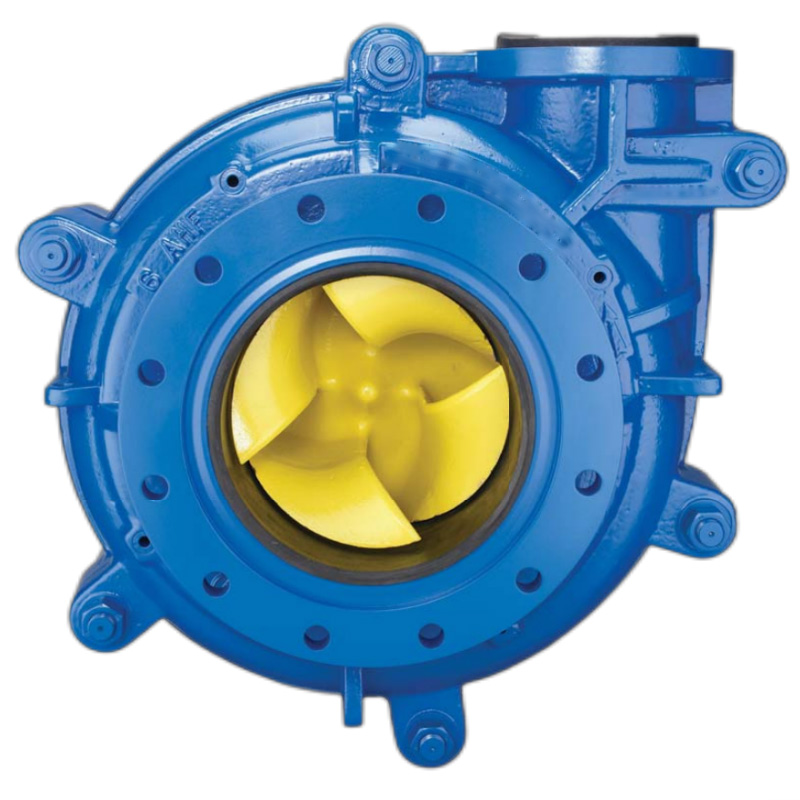

1.5/1B-THR Rubber Lined Slurry Pump is the standard heavy duty slurry pumps which designed with rubber lined.It is more suitable in delivering strong corrosive or abrasive slurries of small particle size without sharp edges.The rubber lined slurry pumps typically used in process plant transfers,corrosive and caustic wet waste,recycling-washing plants,minerals processing,mineral recovery and chemical process plant.

Design Features:

√Cantilever,horizontal centrifugal rubber lined slurry pump

√Wet end–resistance and corrosive resistance rubber lined wear parts

√maximum working pressure is 3.6Mpa.

√Expeller seal,mechanical seal and packing seal are available.

√The discharge branch can be positioned at interval of 45 degrees by request and oriented to any eight positions to suit installations and applications.

√To adapt to convey heavy abrasion,high concentration dredge,slurry pump’s body is used double-shell construction,in other words,being made of inside lining and outside casing.

1.5/1 B THR Rubber Lined Slurry Pump Performance Parameters:

|

Model |

Max. Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q (m3/h) |

Head H (m) |

Speed n (rpm) |

Eff. η (%) |

NPSH (m) |

|||

|

1.5/1B-AHR |

15 |

Rubber |

Rubber |

10.8-25.2 |

7-52 |

1400-3400 |

35 |

2-4 |

3 |

Rubber Lined Slurry Pumps Sealing Arrangement:

Packing Seal

As one of the most commonly used seals for rotating shafts,the packing seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing.This kind of seal is suitable for use under all pumping conditions.In situations where corrosive solids or high temperature might be encountered,Teflon or aramid fiber is used as the packing material for the gland.For high abrasion conditions,a ceramic shaft sleeve is available.

Centrifugal Seal-Expeller

The combination of impeller and expeller creates the pressure needed to seal against leakage.Together with the gland seal or lip seal which is used as the shut-down seal,this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site,or sealing water is allowed to enter inside the pumping chamber to dilute the slurry.

Mechanical Seal

THRR heavy duty slurry pump utilizes a leak-proof mechanical seal design which allows easy installation and replacement.Other types of mechanical seal are among options to suit the slurry pump for various pumping applications.

We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction.Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions.

Rubber Lined Slurry Pumps Applications:

Mining&Mineral Processing

The slow running speeds of the Tobee heavy duty rubber lined slurry pump,together with the comprehensive choice of abrasion resistant alloys and rubber,provide unrivalled performance and service life for all abrasive mining and minerals processing applications.

Chemical Process

The interchangeability of alloy and rubber components in the same pump casing,together with a wide range of mechanical seals,make the Tobee heavy duty rubber lined slurry pump the most flexible choice for the chemical plant environment.

Sand&Gravel

Designed for easy and simple strip down and re-assembly,the Tobee heavy duty rubber lined slurry pump minimises downtime,making it the ideal choice where installed stand by pumps are not available.

Sugar Processing

The premium reliability and service life of the Tobee heavy duty rubber lined slurry pump is specified by many sugar plant engineers worldwide where uninterrupted pump operation during the sugar campaign is a critical requirement.

Flue Gas Desulphurisation

The new generation of specially formulated abrasion and corrosion resistant alloys,together with the very latest rubber technology,positions Tobee Pumps firmly as a major supplier of pumps to the FGD industry.

Oil&Gas Exploration

Over a number of years we have developed the proven design of the Tobee heavy duty rubber lined slurry pump ranges to suit the specific demands of offshore applications.We can now offer the most reliable top side solution to erosive wear.

Industrial Applications

Wherever abrasive solids are causing premature failure of pumps,the Tobee heavy duty rubber lined slurry pump range has the right combination of performance,wear life and reliability to bring the customer the lowest cost of ownership.

Note:

1.5/1 B THR rubber lined slurry pumps and parts are only interchangeable with Warman®1.5/1 AHR rubber lined slurry pumps and parts.

Product detail pictures:

Related Product Guide:

With a complete scientific quality management system, good quality and good faith, we win good reputation and occupied this field for Cheapest Factory Dredge Pump - 1.5/1B-THR Rubber Slurry Pump high quality service – Ruite Pump , The product will supply to all over the world, such as: Saudi Arabia, Orlando, Sevilla, Taking the core concept of "to be the Responsible". We'll redound up on society for high quality merchandise and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.