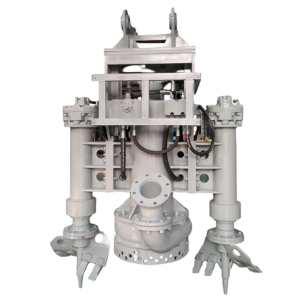

Best-Selling Heavy Duty Process Circuit Mill Discharge Slurry Pump

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Best-Selling Heavy Duty Process Circuit Mill Discharge Slurry Pump, Our Enterprise Core Principle: The prestige initial ;The standard guarantee ;The customer are supreme.

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for China Slurry Pump and Sludge Pump, Adhering to the principle of “Enterprising and Truth-Seeking, Preciseness and Unity”, with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective items and meticulous after-sales service. We firmly believe that: we have been outstanding as we have been specialized.

8/6E-THR Rubber Lined Slurry Pump is the standard heavy duty slurry pumps which designed for the continuous pumping of highly abrasive, high density slurries with minimal maintenance requirements, It maintains high efficiencies over the wear life of its components. 8/6 slurry pump typically used in process plant transfers, wet waste processes, recycling-washing plants, sand plant duties, heavy minerals processing, mineral recovery and chemical process plant.

Design Features:

√ Heavy duty construction with through-bolt design provides ease of maintenance and minimal downtime

√ Ductile iron fully lined casing provides durability, strength, safety, and long service life

√ Large diameter, slow turning, high efficiency impellers designed to achieve maximum wear life and low operating costs

√ Large, open internal passages designed to reduce internal velocities, maximize wear life and lower operating costs

√ Thick rubber or alloy bolt-in liners provide superior corrosion resistance plus offer ease of liner change-out and interchangeability to reduce overall maintenance costs and maximize wear life

√ Minimal shaft/impeller overhang reduces shaft deflection and increases packing life

√ Cartridge-style bearing assembly allows for maintenance in a clean environment without removal of the pump, resulting in reliable operation and prolonged bearing life

√ Grease or oil lubrication bearing assembly options offer ease of maintenance and reduced downtime

√ Optional dry running shaft seal reduces or eliminates flush water requirements

√ Effective expeller prolongs packing life while reducing or eliminating flush water requirement

8/6 E THR Rubber Lined Slurry Pump Performance Parameters:

|

Model |

Max. Power (kw) |

Materials |

Clear water performance |

Impeller Vane No. |

|||||

|

Liner |

Impeller |

Capacity Q (m3/h) |

Head H (m) |

Speed n (rpm) |

Eff. η (%) |

NPSH (m) |

|||

|

8/6E-THR |

120 |

Rubber |

Rubber |

324-720 |

7-49 |

400-1000 |

65 |

5-10 |

5 |

Note:

8/6 E THR rubber lined slurry pumps and parts are only interchangeable with Warman® 8/6 E THR rubber lined slurry pumps and parts.It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Best-Selling Heavy Duty Process Circuit Mill Discharge Slurry Pump, Our Enterprise Core Principle: The prestige initial ;The standard guarantee ;The customer are supreme.

Best-Selling China Slurry Pump and Sludge Pump, Adhering to the principle of “Enterprising and Truth-Seeking, Preciseness and Unity”, with technology as the core, our company continues to innovate, dedicated to providing you with the highest cost-effective items and meticulous after-sales service. We firmly believe that: we have been outstanding as we have been specialized.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |