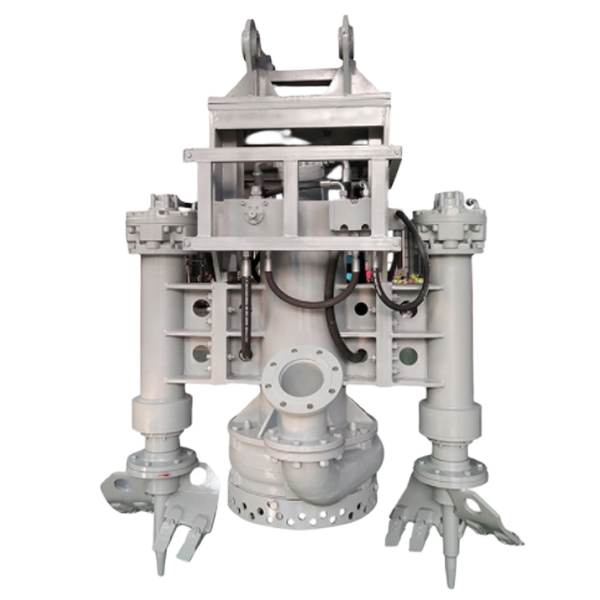

Best quality Sp Slurry Pump - 300TV-TSP Vertical Slurry Pump – Ruite Pump

Best quality Sp Slurry Pump - 300TV-TSP Vertical Slurry Pump – Ruite Pump Detail:

300TV-TSP Vertical Slurry Pump is designed to be immersed in liquid for conveying abrasive, coarse particles, dirty water and particle contaminated water. Due to the design of the pump assembly, a shaft seal is not required and the pump can be operated in conditions that most pumps would have a low service life and their seal arrangement would not be effective.

Design Features

• Fully Cantilevered – Eliminates submerged bearings, packing, lip seals, and mechanical seals that other vertical slurry pumps typically require.

• Impellers – Unique double suction impellers; fluid flow enters the top as well as the bottom. This design eliminates shaft seals and reduces thrust load on the bearings.

• Large Particle – Large particle impellers are also available and enable passing unusually large solids.

• Bearing Assembly – The maintenance friendly bearing assembly has heavy duty roller bearings, robust housings, and a massive shaft.

• Casing – The metal pumps have a heavy walled abrasive resistant Cr27Mo chrome alloy casing. Rubber pumps have a molded rubber casing adhered to sturdy metal structures.

• Column and Discharge Pipe – The metal pump columns and discharge pipes are steel, and the rubber columns and discharge pipes are rubber covered.

• Upper Strainers – Snap in elastomer strainers fit in column openings to prevent overly large particles and unwanted refuse from entering casing of the pump.

• Lower Strainers – Bolt-on cast strainers on the metal pump and molded snap-on elastomer strainers on the rubber pumps protect the pump from oversize particles.

300TV SP Vertical Slurry Pumps Performance Parameters

|

Model |

Matching power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff.η (%) |

Impeller dia. (mm) |

Max.particles (mm) |

Weight (kg) |

|

300TV-TSP(R) |

22-200 |

288-1267 |

6-33 |

350-700 |

50 |

610 |

65 |

3940 |

300 TV-TSP Vertical Slurry Pumps Applications

300 TV – TSP sump slurry pump is widely used in mining, mineral processing, sand and gravel, coal, chemical grout services, processing, wet crusher, cyclone feed, aggregate and a half since the mill discharge, a grinding machine for grinding, tailings, the secondary grinding, bottom ash/fly ash slurry, pulp and paper, food processing, cracking, gypsum slurry pipeline transport,, High-speed hydraulic transport, food processing, metal smelting in the explosive and dredging of river and pond sludge, garbage removal, the application of large particles or low NPSHA and continuous (snoring) sump pump operation, grinding mud, mud high-density mud, large particles, sump drainage, irrigation, surface drainage, mixing, iron ore, copper, diamonds, aluminum oxide, gold, kaolin,, Phosphorite, iron and steel, palm, sugar, chemical industry, electric power, flue gas desulfurization, fracturing sand mixing, wastewater, flotation, etc.

Note:

300 TV-TSP vertical slurry pumps and spares are only interchangeable with Warman® 300 TV-SP vertical slurry pumps and spares.

Product detail pictures:

Related Product Guide:

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for Best quality Sp Slurry Pump - 300TV-TSP Vertical Slurry Pump – Ruite Pump , The product will supply to all over the world, such as: Jordan, venezuela, Afghanistan, Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to deliver customers with high quality solutions, present high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

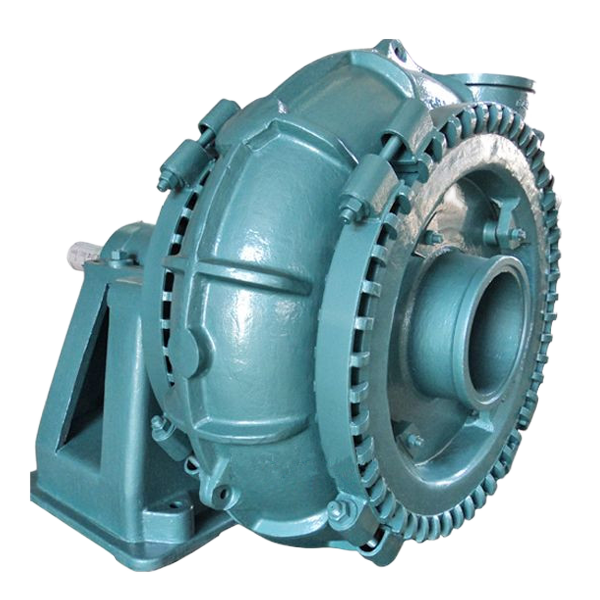

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.