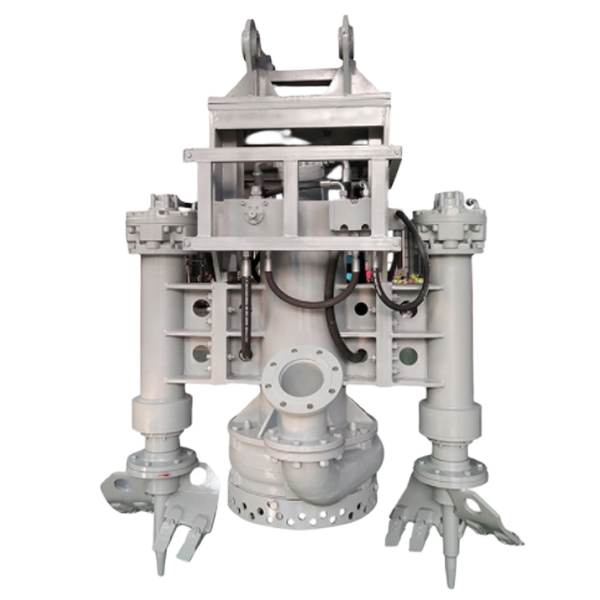

250TV-TSP Vertical Slurry Pump – Shijiazhuang

250TV-TSP Vertical Slurry Pump – Shijiazhuang Detail:

250TV-TSP Vertical Slurry Pump is no submerged bearings or seals heavy duty cantilevered pumps, which ideal for a variety of submerged suction pumping applications. These pumps operate well in a variety of sump conditions, and can also be readily applied on floating dewatering or other floating pump platforms.

Design Features

• Bearing assembly — the bearing, shaft and housing ratio is very large to avoid problems with cantilever shaft operation in the first critical speed zone.

The components are lubricated with grease and sealed through a labyrinth; The top is cleaned with grease and the bottom is protected with a special lighter. The upper or driving end bearings are parallel roller type and the lower bearings are double tapered rollers with preset end floats. This high performance bearing configuration and rugged shaft does not require lower underwater bearings.

• Column Assembly – Completely fabricated from mild steel. The SPR model is elastomer covered.

• Casing – Has a simple bolt-on attachment to the base of the column. It is manufactured from a wear resistant alloy for the SP and from moulded elastomer for the SPR.

• Impellers — Double suction impellers (top and bottom inlets) generate lower axial bearing loads and have heavy duty deep blades for maximum wear resistance and handling of large solids. Wear resistant alloy, polyurethane and molded elastomer impeller are interchangeable. During assembly, the impeller is adjusted axially within the casting by means of an external gasket under the base of the bearing seat. No further adjustment is required.

• Upper Strainer – Drop-in metal mesh, snap-on elastomer or polyurethane for SP and SPR pumps. Strainers fit in column openings.

• Lower Strainer – Bolted metal or polyurethane for SP, moulded snap-on elastomer for SPR.

• Discharge Pipe – Metal for SP, elastomer covered for SPR. All wetted metal parts are completely rust protected.

• Submerged Bearings – None

• Agitator — Optional external agitator spray connection mounted on the pump. Alternatively, the mechanical stirrer is mounted on an extension shaft extending from the impeller hole.

• Materials – Pumps can be manufactured in abrasive and corrosive resistant materials.

250TV-TSP Vertical Slurry Pumps Performance Parameters

|

Model |

Matching power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff.η (%) |

Impeller dia. (mm) |

Max.particles (mm) |

Weight (kg) |

|

250TV-TSP(R) |

18.5-200 |

261-1089 |

7-33.5 |

400-750 |

60 |

575 |

65 |

3700 |

250 TV SP Vertical Cantilever Pump On-site Applications

• Mining

• Mineral processing

• Construction

• Chemical and Fertilization

• Power generation

• Ball mill discharge

• Rod mill discharge

• SAG mill discharge

• Fine tailings

• Flotation

• Heavy media process

• Minerals concentrate

• Mineral sands

Note:

250 TV-TSP vertical slurry pumps and spares are only interchangeable with Warman® 250 TV-SP vertical slurry pumps and spares.

Product detail pictures:

Related Product Guide:

"Control the standard by the details, show the power by quality". Our business has strived to establish a highly efficient and stable team staff and explored an effective good quality regulate course of action for 250TV-TSP Vertical Slurry Pump – Shijiazhuang , The product will supply to all over the world, such as: UK, Swiss, Canberra, All our products are exported to clients in the UK, Germany, France, Spain, the USA, Canada, Iran, Iraq, the Middle East and Africa. Our products are well welcomed by our customers for the high quality, competitive prices and the most favorable styles. We hope to establish business relationship with all customers and bring more beautifu colors for the life.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.