18 Years Factory Slurry Pumps & Engineers - Slurry pump Volute Liner – Ruite Pump

18 Years Factory Slurry Pumps & Engineers - Slurry pump Volute Liner – Ruite Pump Detail:

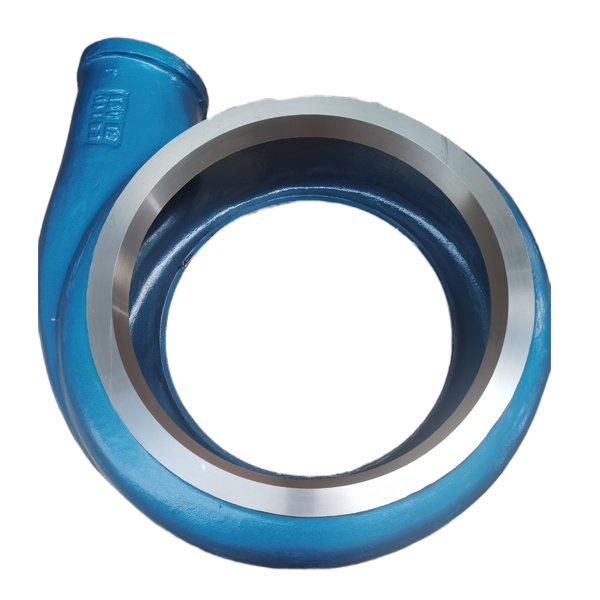

Slurry pump Volute Liner is an important wear part of slurry pumps. It forms a slurry pump chamber with throat bush and frame plate liner insert where the slurry would flow through them.

Liner is also one of wet parts of slurry pumps. It forms a pump chamber with throatbush and frame plate liner insert where the slurry would flow through them.

Slurry volute Liner is a curved funnel increasing in area to the discharge port. It is often used with slurry pump impeller. As the area of the cross-section increases, the volute reduces the speed of the liquids and increases the pressure of the liquids. The main purposes of a volute liner is to help balance the hydraulic pressure on the shaft of the slurry pump.

slurry pump parts are dimensionally interchangeable with warman slurry pump parts and other brand slurry pumps. And more, we accept pump parts OEM and ODM business, especially abrasion and corrosion pump parts. Ruite own foundry and compound specialist to increase the wet parts wear life time, and We have been tested by end users plant of the most abrasive and most corrosive arduously applications. and also welcome the opportunity to discuss your applications in more detail. Our experienced technical engineers are always ready to give advice and make suggestions to improve future wear life of your slurry pumps. We are capable enough to help you work out a perfect casting material ingredient for special slurries.

Slurry Pump Volute Liners Code:

|

Volute Liner Code |

AH Slurry Pump |

Volute Liner Materials |

|

B1110 |

1.5/1B-AH |

High chrome, Natural rubber, Polyurethane |

|

B15110 |

2/1.5B-AH |

High chrome, Natural rubber, Polyurethane |

|

C2110 |

3/2C-AH |

High chrome, Natural rubber, Polyurethane |

|

D3110 |

4/3C-AH, 4/3D-AH |

High chrome, Natural rubber, Polyurethane |

|

E4110 |

6/4D-AH, 6/4E-AH |

High chrome, Natural rubber, Polyurethane |

|

F6110 |

8/6E-AH, 8/6F-AH |

High chrome, Natural rubber, Polyurethane |

|

G8110 |

10/8F-AH, 10/8ST-AH |

High chrome, Natural rubber, Polyurethane |

|

G10110 |

12/10F-AH, 12/10ST-AH |

High chrome, Natural rubber |

|

G12110 |

14/12F-AH, 14/12ST-AH |

High chrome, Natural rubber |

|

H14110 |

16/14TU-AH |

High chrome, Natural rubber |

|

Volute Liner Code |

HH Slurry Pump |

Volute Liner Materials |

|

CH1110 |

1.5/1C-HH |

High chrome |

|

DH2110 |

3/2D-HH |

High chrome |

|

EH3110 |

4/3E-HH |

High chrome |

|

FH4110 |

6/4F-HH |

High chrome |

|

FH4110 |

6-H |

High chrome |

|

Volute Liner Code |

M Slurry Pump |

Volute Liner Materials |

|

F8110 |

10/8E-M, 10/8F-M,10/8R-M |

High chrome, Natural rubber, Polyurethane |

|

F10110 |

12/10E-M, 12/10F-M |

High chrome, Natural rubber, Polyurethane |

|

Volute Liner Code |

L Slurry Pump |

Volute Liner Materials |

|

AL2110 |

20A-L |

High chrome, Natural rubber |

|

BL5110 |

50B-L |

High chrome, Natural rubber |

|

CL75110 |

75C-L |

High chrome, Natural rubber |

|

DL10110 |

100D-L |

High chrome, Natural rubber |

|

EL15110 |

150E-L |

High chrome, Natural rubber |

|

SL20110 |

200E-L |

High chrome, Natural rubber |

|

SL30110 |

300S-L |

High chrome, Natural rubber |

|

SL35110 |

350S-L |

High chrome, Natural rubber |

|

TL40110 |

400ST-L |

High chrome, Natural rubber |

|

TL45110 |

450ST-L |

High chrome, Natural rubber |

|

UL55110 |

550TU-L |

High chrome, Natural rubber |

Note:

slurry pump volute liners are only interchangeable with Warman® slurry pump volute liners

Product detail pictures:

Related Product Guide:

The shopper satisfaction is our primary focus on. We uphold a consistent level of professionalism, quality, credibility and repair for 18 Years Factory Slurry Pumps & Engineers - Slurry pump Volute Liner – Ruite Pump , The product will supply to all over the world, such as: Jamaica, Tunisia, venezuela, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!