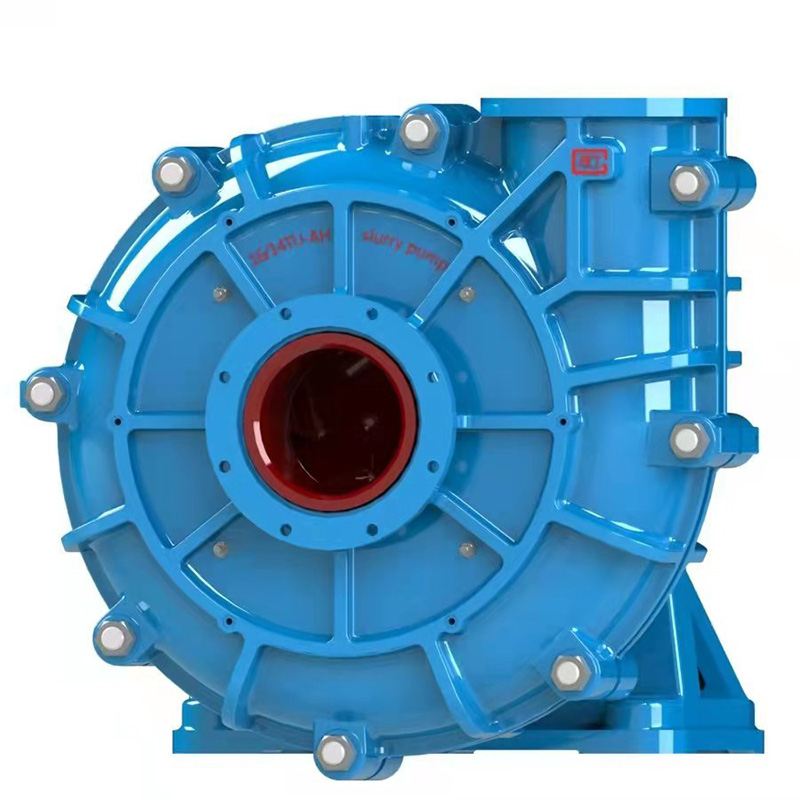

14/12T-TG Gravel Pump, Various drive types, interchangeable with Warman pumps – Ruite Pump

14/12T-TG Gravel Pump, Various drive types, interchangeable with Warman pumps – Ruite Pump Detail:

14x12T-TG Gravel pump is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Its wear parts made from high chrome alloy, The hardness can upto HRC65, Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life.

Design Features

• Bearing assembly — Large diameter shaft with short overhang helps extend bearing life.

• Linings — Easily replaceable linings are bolted rather than glued to the housing for active maintenance.

• Housing — Semi-cast iron or ductile iron housing provides high working pressure capability.

• Impellers — Front and rear shields are equipped with pumping blades to reduce recirculation and seal contamination.

• Throat bushings — Use tapered bushings to reduce wear and simplify maintenance.

14/12T-TG Gravel Pump Performance Parameter

|

Model |

Max. Power P (kw) |

Capacity Q (m3/h) |

Head H (m) |

Speed n (r/min) |

Eff. η (% ) |

NPSH (m) |

Impeller Dia. (mm) |

|

14x12T-TG |

1200 |

576-3024 |

8-70 |

300-700 |

68 |

2-8 |

864 |

14/12T-TG Gravel Pump Applications

• Mining

• Dredging

• Sand Reclamation

• Sand Excavation

• Tunnel

• Cyclone Feed

• Barge Loading

• Dredger

• Pipe-jacking system

• Mill Discharge

• Slag Granulation

• Coarse sand

• Blast slag

• Suction Hopper Dredging

• Tailings

• Construction

• Ash handing

• Power Plant

• Mineral processing

• Other industries

Note:

14×12 T-TG gravel dredge pumps and spares are only interchangeable with Warman® 14×12 T-G gravel dredge pumps and spares.

Product detail pictures:

Related Product Guide:

To regularly increase the management program by virtue from the rule of "sincerely, good religion and high quality are the base of enterprise development", we greatly absorb the essence of linked products internationally, and constantly produce new goods to satisfy the calls for of shoppers for 14/12T-TG Gravel Pump, Various drive types, interchangeable with Warman pumps – Ruite Pump , The product will supply to all over the world, such as: Israel, Paris, Brunei, We are adhering to the philosophy of "attracting customers with the best products and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

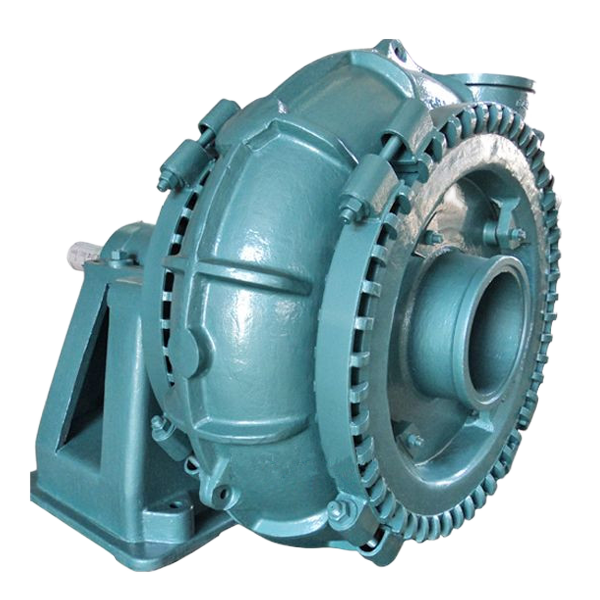

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Material Code | Material Description | Application Components |

| A05 | 23%-30% Cr White Iron | Impeller, liners, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, liners |

| A49 | 27%-29% Cr Low Carbon White Iron | Impeller, liners |

| A33 | 33% Cr Erosions & Corrosion Resistance White Iron | Impeller, liners |

| R55 | Natural Rubber | Impeller, liners |

| R33 | Natural Rubber | Impeller, liners |

| R26 | Natural Rubber | Impeller, liners |

| R08 | Natural Rubber | Impeller, liners |

| U01 | Polyurethane | Impeller, liners |

| G01 | Grey Iron | Frame plate, cover plate, expeller, expeller ring, bearing house, base |

| D21 | Ductile Iron | Frame plate, cover plate, bearing house, base |

| E05 | Carbon Steel | Shaft |

| C21 | Stainless Steel, 4Cr13 | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C22 | Stainless Steel, 304SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| C23 | Stainless Steel, 316SS | Shaft sleeve, lantern ring, lantern restrictor, neck ring, gland bolt |

| S21 | Butyl Rubber | Joint rings, joint seals |

| S01 | EPDM Rubber | Joint rings, joint seals |

| S10 | Nitrile | Joint rings, joint seals |

| S31 | Hypalon | Impeller, liners, expeller ring, expeller, joint rings, joint seals |

| S44/K S42 | Neoprene | Impeller, liners, Joint rings, joint seals |

| S50 | Viton | Joint rings, joint seals |

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.